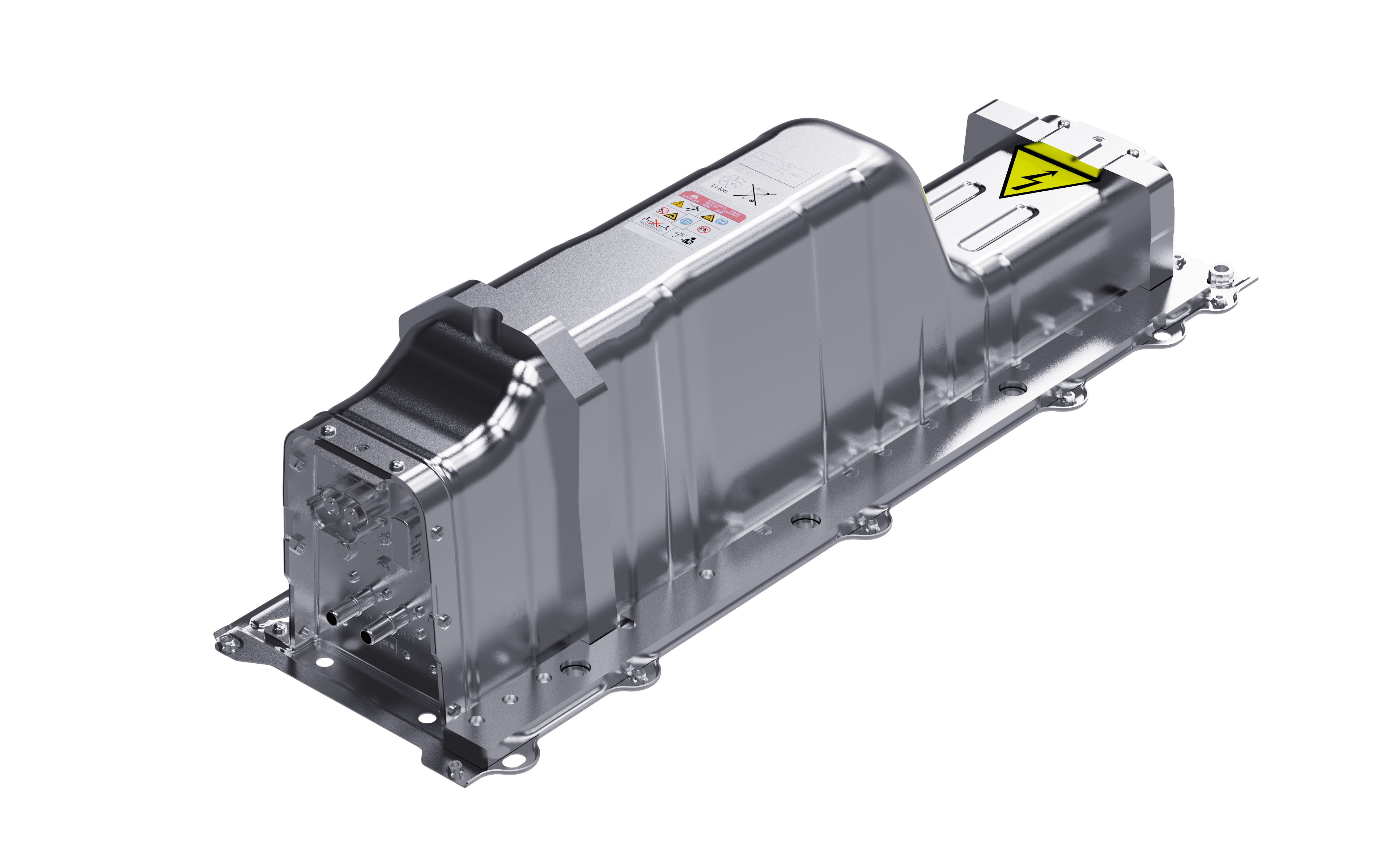

Highly Integrated EV Battery Packs

Excellence in Power with Compatibility for All Vehicle Models

Utilizing an industry-leading and diverse technological approach and full-stack self-development capabilities to address concerns such as safety, performance, and supply anxieties, creating a comprehensive solution for new energy power batteries.

With 12 automated production lines and 16 flexible production lines, compatible with a product series ranging in power capacity from 15.5 kWh to 100 kWh, our annual production capacity reaches 1.047 million pack sets. Utilizing leading domestic and international equipment brands, we perform testing, laser welding, screw fastening, six-axis robot module assembly, automated gluing, and both online and offline AGV logistics turnover. Our smart management system ensures consistent quality and reliable supply.

Vollständiges Video

Four Advantages

EV Solutions

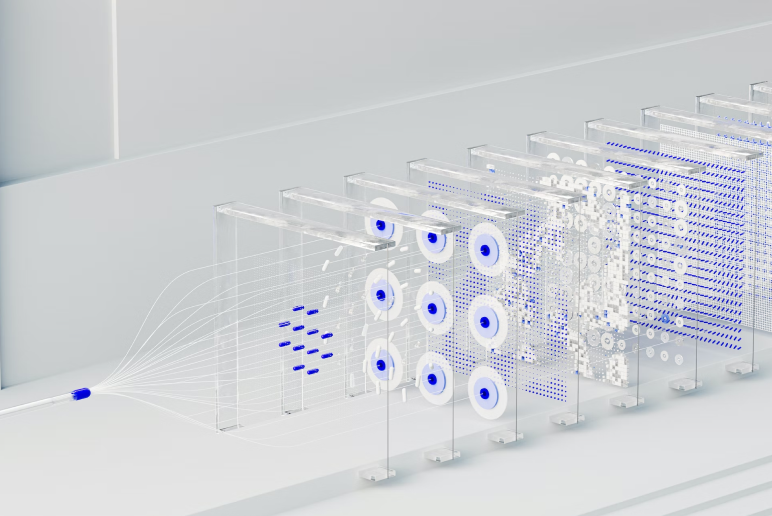

Ultimate Integration

CTP high integration reduces component count by 35%, achieving a maximum volume utilization rate of 83.7% and a 10% increase in energy density.

Ultra-fast Charging Technology

15-minute charging extends range by 500km. 5-minute ultra-fast charging provides a range of over 235 km. Charge 1kWh in just 10 seconds. (Note: Based on a CLTC range of 720 km and a 95kWh pack configuration)

Ultimate Safety Technology

Inheriting the brand's safety DNA, our batteries feature eight layers of thermal safety protection: "Cloud""Prevention", "Isolation", "Absorption", "Cooling","Alert","Discharging", "Disconnection". We offer the industry's first power battery capable of withstanding a 240-second fire test, far exceeding the national standard of 130 seconds. Our batteries are also the first in the industry to withstand six consecutive safety tests, including submersion, fire, freezing, dragging, crushing, and high-altitude drops, without exploding, emitting smoke, catching fire, or experiencing thermal runaway

800V Platform Technology

Industry-leading 800V high-voltage safety protection technology integrates active safety features such as BPS and PSS for millisecond-level power cutoff. Our architecture platform technology is compatible with all models based on the SEA-1+ and SEA-2+ platforms.

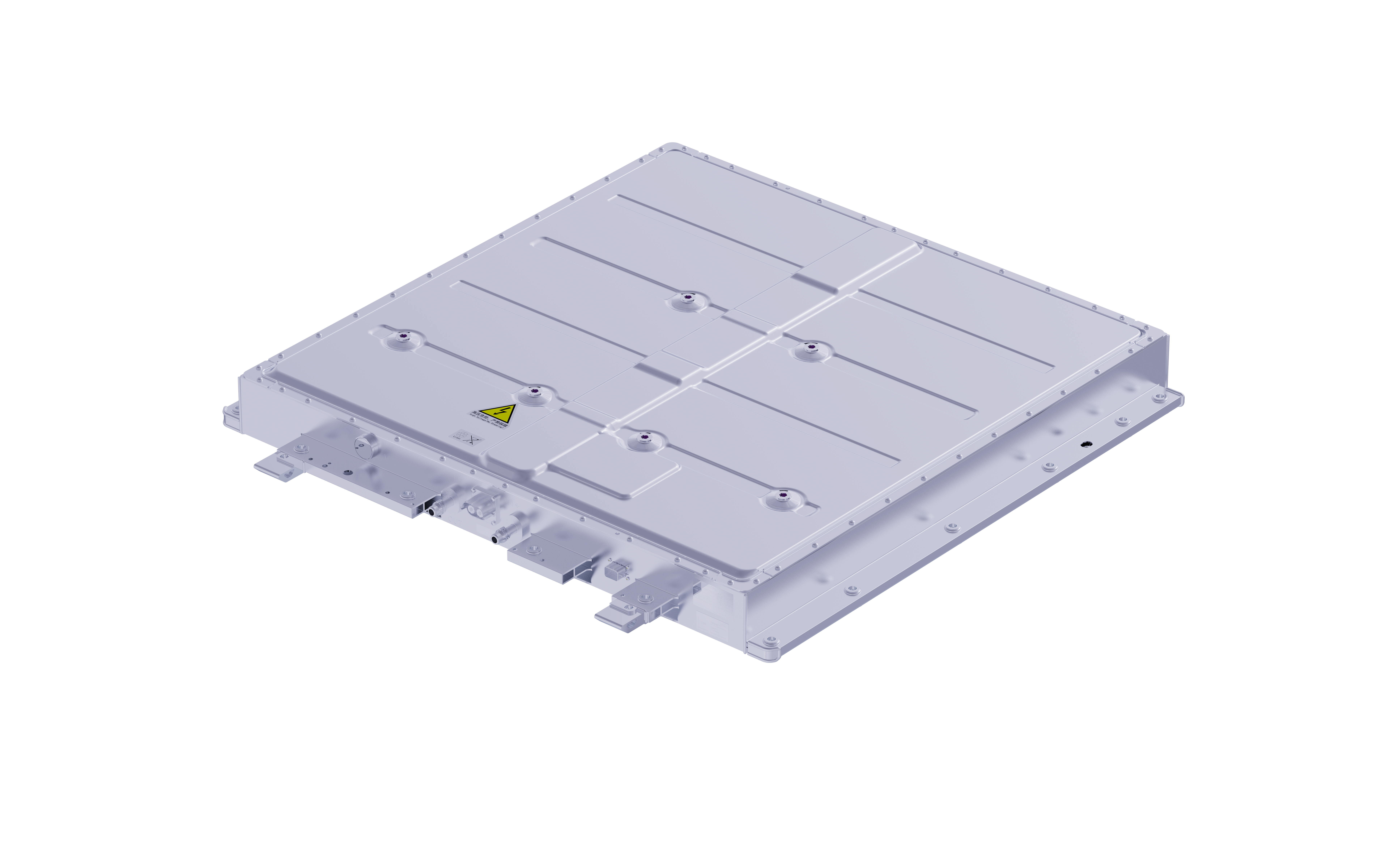

PHEV Solutions

Extended Pure Electric Range

With an energy density of up to 145Wh/kg, high-nickel ternary cathode materials are employed in the battery cells.

More Efficient Thermal Management

Innovative dual-sided liquid cooling technology significantly increases heat dissipation area and greatly enhances system cooling capability.

Lightweight Design

For the first time, a top cover with a thickness of 0.7mm sheet metal is used, along with a highly integrated triple-layer stacked module and Pack design, achieving high space utilization and lightweight properties.

Higher Safety Assurance

Multiple safety designs and advanced management strategies meet multiple safety requirements such as mechanical and electrical properties, and reduce weight without reducing strength, meeting security standards of Volvo.

Higher Compatibility and Adaptability

Meet global standards.

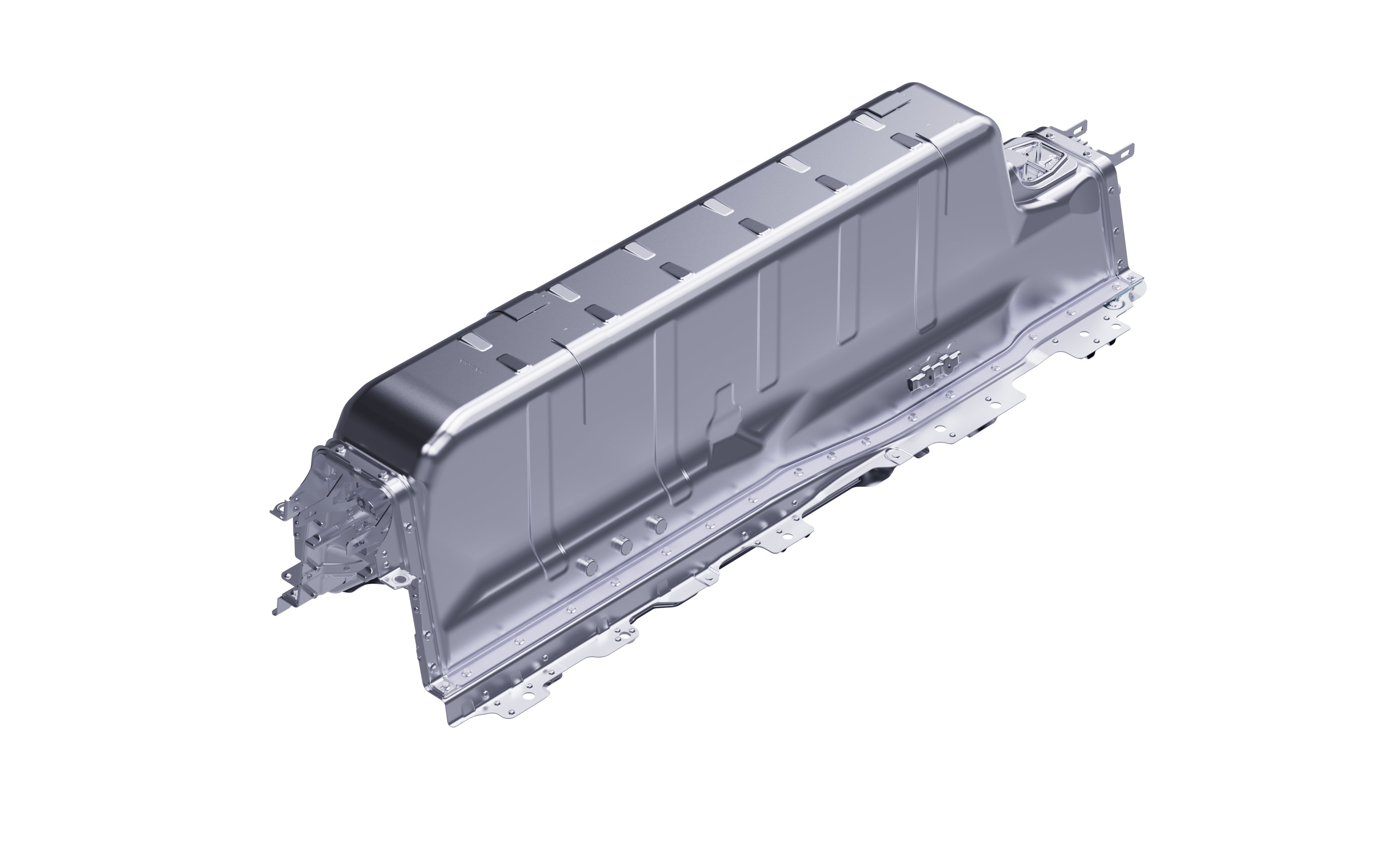

HEV Solutions

Higher Charging/Discharging Power

Excellent charging and discharging rate performance: 60 kW @ 10s @ 50% SOC, effectively enhances vehicle dynamics and fuel economy.

High Integration

Utilizes a large module stacking design for high grouping efficiency. BDU high-voltage control box integrates BMS, and electrical components, etc. Modular layered design for compact structure and lighter weight.

More Efficient Thermal Management

Incorporates an innovative three-sided surrounding liquid-cooled flat tube integrated module design. In addition to conventional module bottom cooling, the module's side is fully utilized for rapid heat dissipation. This reduces cooling time, minimizes temperature differentials, significantly increases heat dissipation efficiency, and reduces overall vehicle fuel consumption.

Cooperation Cases

Umfassende Lösung

Bieten wir Ihnen fortschrittliche Produkte und professionelle Lösungen