产品研发

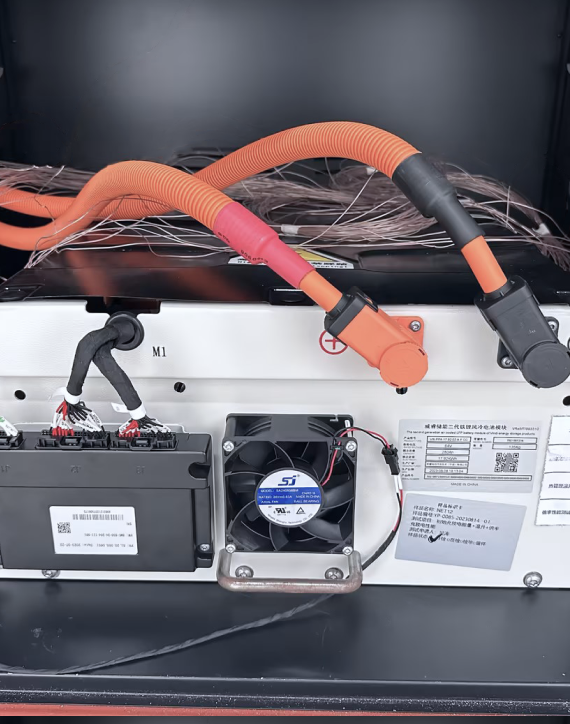

电池研发

电驱研发

充电研发

储能研发

发明专利

经过3000多研发人员不懈努力,威睿能源在技术研发、设计应用、工艺制造、试验试制等方面已布局提报1300余项专利,其中包含发明专利431余项,涵盖电芯、模组、PACK、BMS、电机电控、储能产品等核心技术,并已分阶段进行国际专利布局。

试验能力

威睿电动实验室建筑面积37000平方米,检测设备投资约3亿元,现有检测及支持人员共计162人,其中本科及以上106人,占比65%,检测经验5年以上130人,占比80%。电池领域测试专家1人。试验领域涵盖材料及电化学、动力电池、电机电控、充电系统、储能系统、电磁兼容EMC、环境可靠性检测等,具备从材料级到零部件级再到系统联调级的试验能力,满足GB、ISO、UN、UL、ECE等国内测试外标准和吉利、VOLVO、领克等企业标准。实验室严格按照ISO/IEC 17025标准的要求建立和运行,已通过中国合格评定国家认可委员会CNAS认可和吉利集团SQE认可,同时实验室为TÜV UN regulation No.100目击实验室。2021年与国网供电公司杭湾供电分公司共同成立了“宁波前湾新型电力系统(储能)联合实验室”。

质量保证

全面、可信赖的全流程质量运营管理

质量系统涵盖研发质量、制造质量、质量改进、供应商管理等,实施全流程质量运营管理,产品得到包括极氪、吉利、吉利银河、领克、几何、VOLVO、极星、smart等客户青睐。

完善的硬件和软件质量保证能力

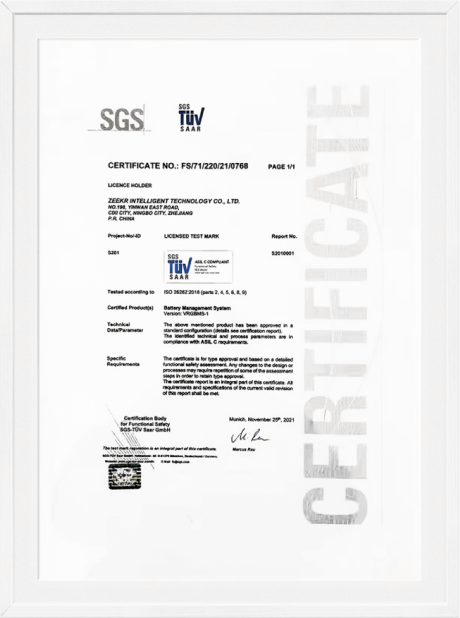

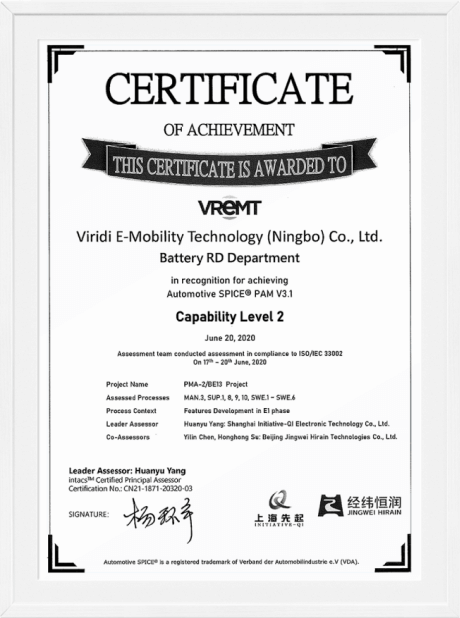

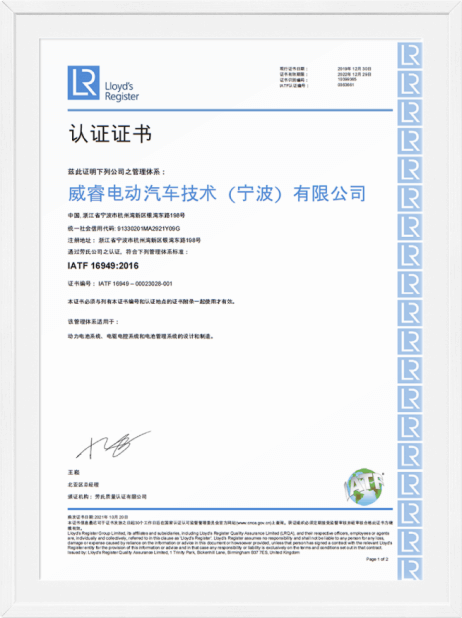

通过IATF 16949质量管理体系认证、ISO/IEC 17025 CANS实验室认证、ASPICE Level -2 流程认证、ISO 26262 功能安全产品认证,以及吉利汽车集团全流程竞争力质量体系 A 级评价。

先进、科学的检验及分析能力

拥有从车规级到工业级的零部件、总成,具备动力电池EOL测试系统、电驱NVH Discom测试台架、电控100%老化测试系统,建有三坐标精测室、标准化金相室、清洁度分析室、齿轮测量中心等。

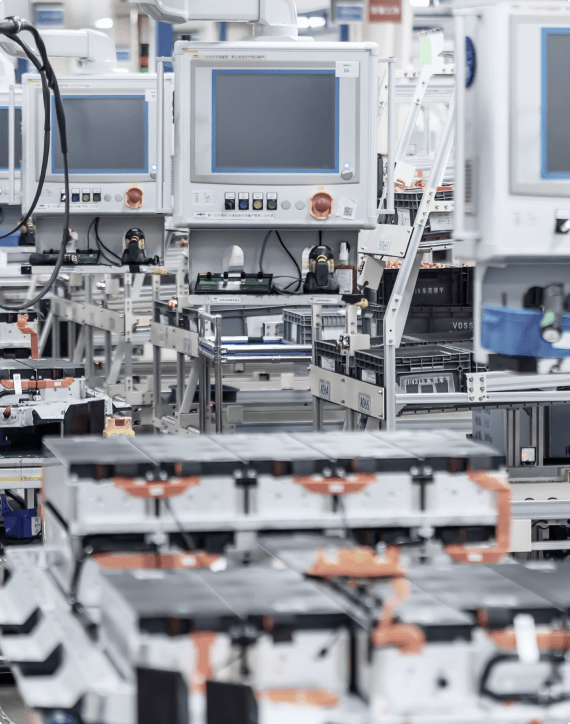

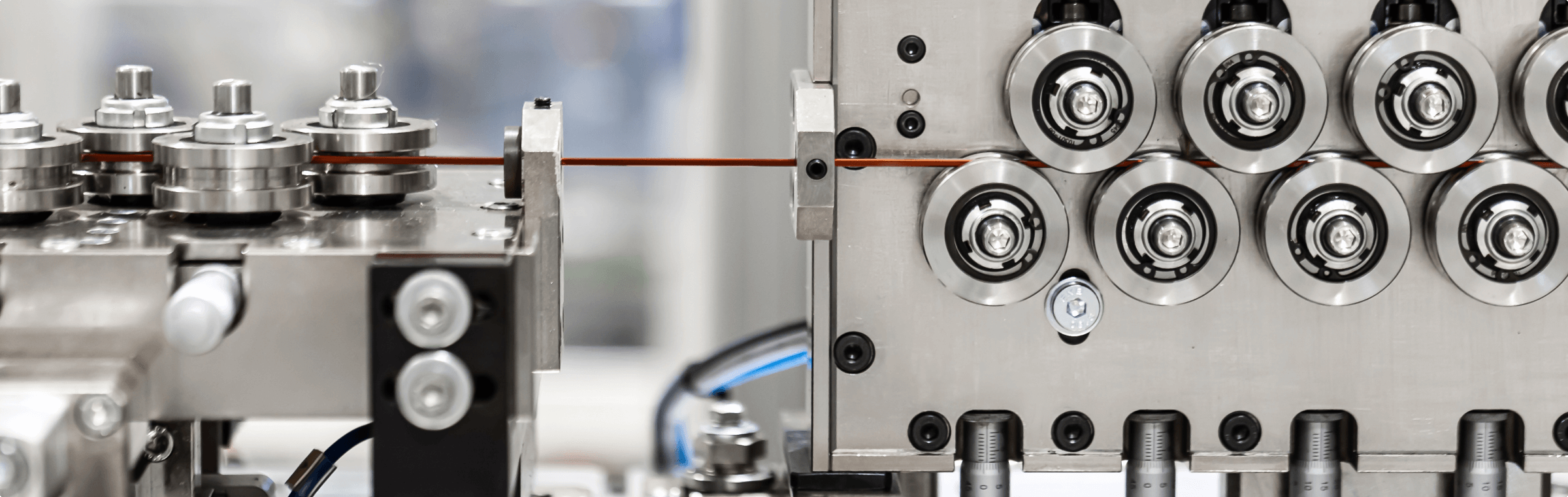

生产制造

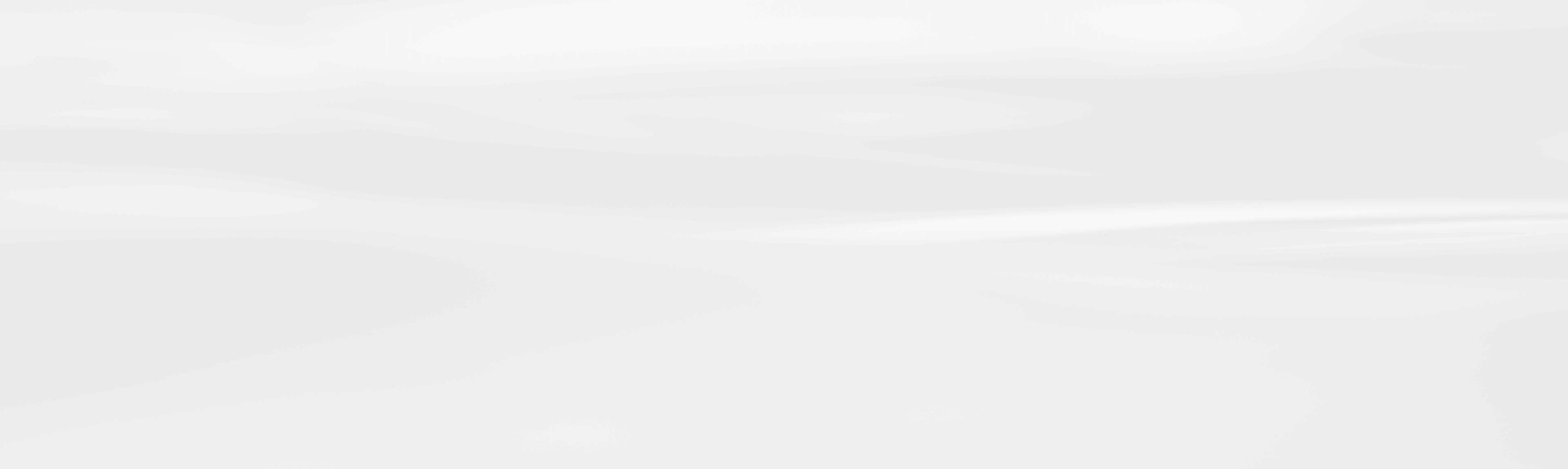

电池产品线

电池产品线

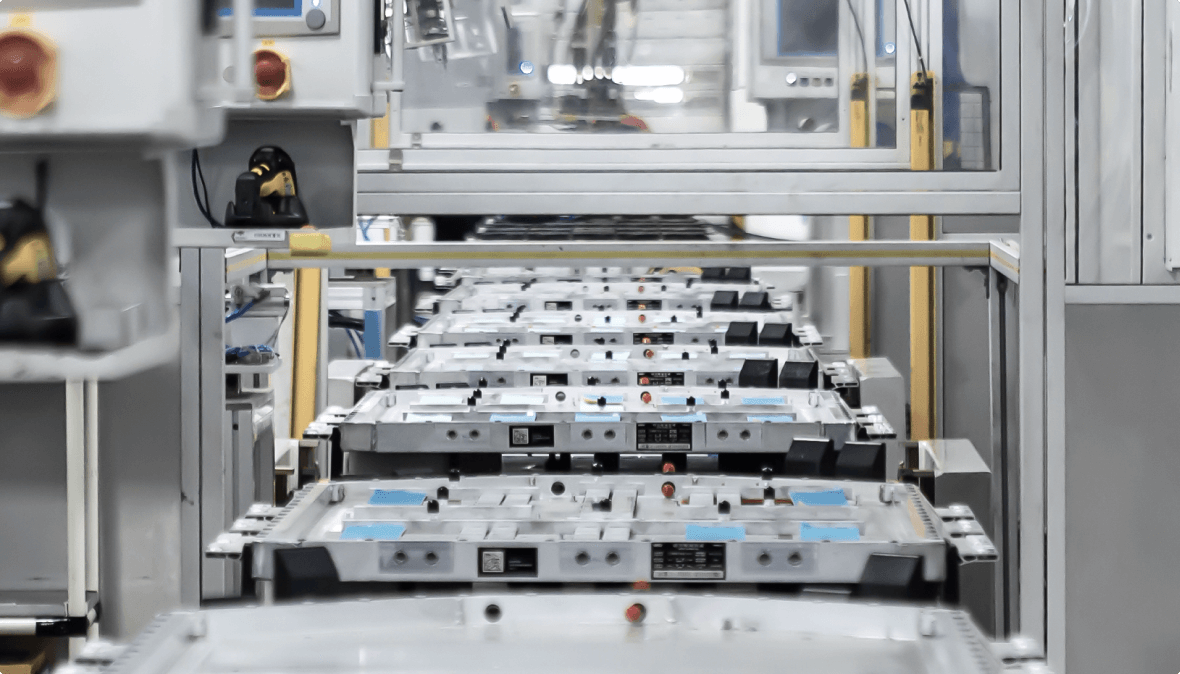

电驱产品线

电驱产品线

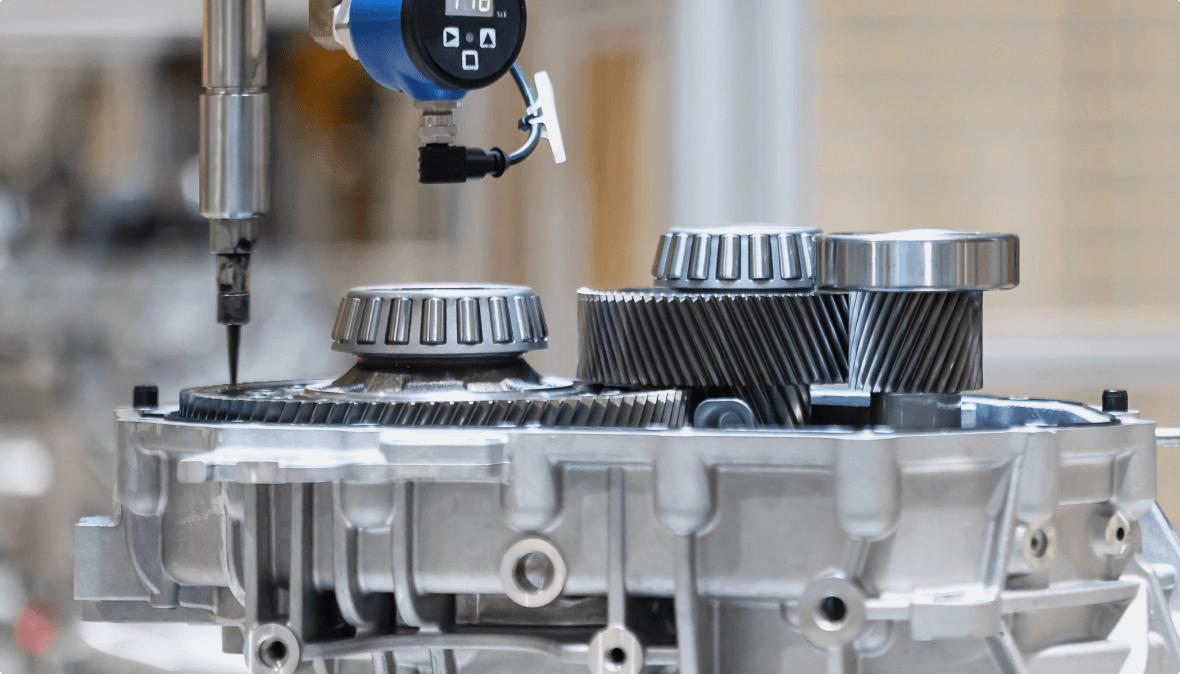

电子产品线

电子产品线

超充产品线

超充产品线