With the continuous development of the new energy sector, the EV battery field has increasingly favored 800V battery packs over the previous 400V ones, as they enhance charging power and driving power. VREMT, keeping pace with the times, has positioned itself at the forefront of the industry. The company has established a globally leading R&D and manufacturing system, consistently innovating in areas such as electric vehicle power battery packs, electric drive systems, charging systems, and industrial energy storage systems.

For users, safety is a top priority, and VREMT consistently sets safety as the baseline, pushing technological limits to innovate and provide the ultimate safety protection for users' travel security.

Compared to similar battery packs, VREMT’s safety measures start with controlling the raw materials of the battery cells. The LFP cathode uses a more stable cobalt-free material and does not contain other precious metals. Its olivine crystal structure is more stable, fundamentally avoiding oxygen release and thermal runaway reactions in the battery pack. The anode utilizes carbon material with lower capacity density but higher structural stability.

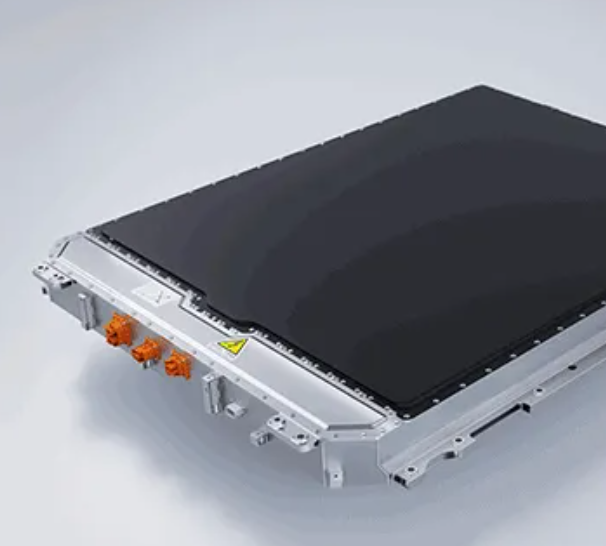

In today’s rapidly developing society, the trend toward high-voltage, high-current charging is inevitable due to the various uncertainties encountered during travel. As a result, the safety testing standards for battery packs have naturally risen. VREMT’s 800V battery pack maintains high standards with an “interior-exterior prevention” strategy, continually raising material standards and employing both invisible and visible barriers to prevent thermal runaway.

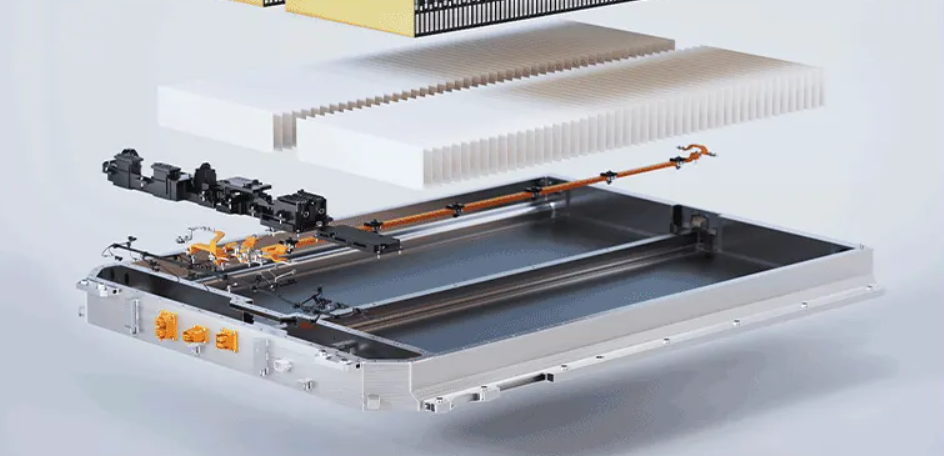

Internally, the VREMT 800V battery pack has upgraded its thermal safety protection from six to eight measures. In addition to the original “prevention, isolation, absorption, discharge, cutoff, and warning” measures, it has added “absorption” and “cloud” measures for more comprehensive protection and stricter standards. This includes the use of a 4000V golden insulation film for complete safety protection and a full-area “fire blanket” isolation design at the bottom, setting the structural partition design of the battery pack system ahead of many other manufacturers. The HPCM phase change material technology, first applied in this field, rapidly reduces the battery pack temperature, representing the new “absorption” measure. The “cloud” measure involves precise management of the battery's entire lifecycle to prevent loss of control due to battery cell wear and aging.

Externally, the battery pack is constructed with a crosswoven three-dimensional structure. The reinforced beams are designed to disperse and absorb impact forces from the outside. Unlike ordinary EV batteries, the VREMT 800V battery pack can withstand the brutal crushing force of a 22-ton road roller (an M41 tank weighs 18.4 tons). Additionally, the battery pack is equipped with an integrated aluminum-manganese alloy insulation liquid cooling plate, which is high-strength, highly thermally conductive, and highly corrosion-resistant. Combined with brazing technology, the battery pack achieves IPX8 waterproofing, making it impervious to urban flooding.

The VREMT 800V battery pack goes beyond high-standard technological pathways, continually pushing the limits of testing standards. By surpassing national and industry standards, it pioneers three extreme tests and serial tests under extreme conditions, ensuring that vehicles can be used without worry, even under harsh conditions. Whether it is the industry's first “crush + puncture” combined rigorous safety test or the far-exceeding standard external fire test, the 800V battery pack remains free from fire or explosion. After enduring continuous “immersion, burning, freezing, dragging, crushing, and high drop” tests, it remains stable, with safety testing intensity far exceeding that of general power battery manufacturers.

In today's evolving new energy sector, while most power battery manufacturers are still focused on battery pack pricing, VREMT Energy continues to delve into the electric vehicle sector, achieving a comprehensive and full-scenario technological layout for electric vehicles and industrial energy storage, continuously climbing the safety threshold.