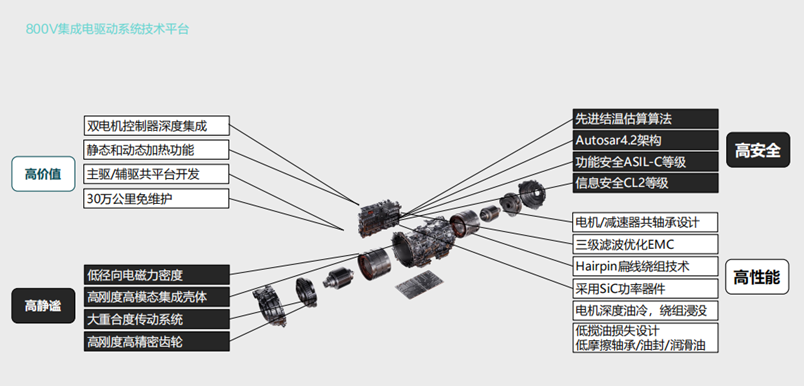

As a leader in the industry, VREMT has been dedicated to R&D and innovation in electric drive systems, continually releasing upgraded products. Here are the key technological advancements in VREMT's iterative electric drivetrain products:

Hardware Integration and Optimization:

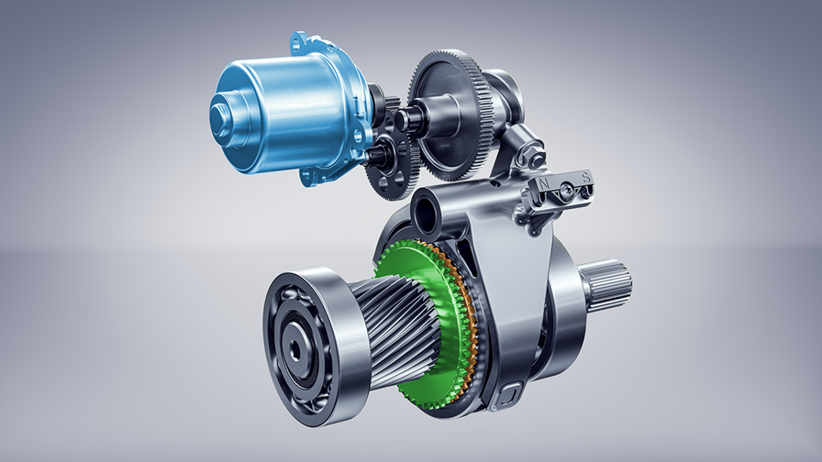

In hardware, VREMT has enhanced overall system performance by optimizing and integrating critical components. The latest 800V Electric Drive features a design deeply integrating dual motor controllers, boosting power density to 8.3 kW/kg and torque density to 11.9 Nm/kg—setting industry benchmarks. Innovations like carbon fiber-wrapped rotors reduce weight, enhance durability, and improve heat dissipation, thereby increasing overall system efficiency. For instance, VREMT's EDS-Disconnect electric drive system decouples drive systems for flexible control and enhanced energy management, significantly boosting performance and reliability.

Thermal Management and Efficiency Enhancement:

VREMT has implemented several upgrades in thermal management and efficiency. The 800V electric drive system utilizes advanced junction temperature estimation algorithms to monitor real-time temperature changes, ensuring safe operation under high loads. Integrated static and dynamic heating functions stabilize performance in extreme temperature conditions. Innovations such as deep oil cooling for motors and immersed winding technology further enhance heat dissipation efficiency, reducing energy losses. For example, VREMT's EDS1-SIC electric drive system, utilizing SIC materials, achieves over 2% improvement in comprehensive efficiency and thermal management.

EMC and Safety Enhancement:

Significant upgrades in electromagnetic compatibility (EMC) and safety have been made. The latest 800V electric drive system features optimized EMC design with triple-level filtering, effectively reducing electromagnetic interference. Compliant with ISO 26262 functional safety standards up to ASIL-C level, VREMT ensures system safety across various conditions. Information security at CL2 level safeguards data integrity against external attacks and leaks. These safety enhancements provide users with reliable and secure travel experiences. Additionally, VREMT's NDE21 electric drive system (expected mass production in April 2025) offers peak torque upgrades to 4500 N·m, extended maintenance-free lifespan, further enhancing system safety and reliability.

Intelligence and Automation Technology:

In intelligence and automation, VREMT's electric drive systems have made significant strides. The latest 800V system adopts Autosar 4.2 architecture, elevating system intelligence and automated management capabilities. Intelligent control algorithms enable precise power distribution and energy management, enhancing overall operational efficiency. Features like intelligent heating, disconnect, and anti-skid further improve vehicle control and stability, offering heightened performance and user experience.

VREMT Corporation has undergone comprehensive technological innovations in hardware integration, thermal management, EMC compliance, safety enhancement, and intelligence automation. Continuously innovating, each iteration of VREMT's electric drive systems incorporates cutting-edge designs to deliver more efficient, reliable, and intelligent travel experiences for users!