Battery energy density is critical for the range of electric vehicles, influenced by both the cell's energy density and the utilization of battery pack volume. Although LFP batteries have seen increased market penetration due to their high safety and cost-effectiveness, their lower energy density has become a key limitation for demand growth. Enhancing energy density is thus a critical challenge for the development of LFP batteries. Amidst the rapid development of the electric vehicle industry, VREMT has successfully overcome this bottleneck with its revolutionary 800V battery pack technology, achieving an unprecedented volume utilization rate of 83.7% and significantly improving battery energy density, bringing a revolutionary boost to the range of electric vehicles.

The key to the VREMT 800V battery pack’s remarkable achievement in volume utilization lies in its dual innovation in materials and structure. Traditional LFP batteries are often constrained by their material properties and structural design, making it difficult to surpass a volume utilization rate of 70%. However, VREMT has broken through this barrier by raising the figure to 83.7%, achieving a comprehensive surpassing of conventional batteries.

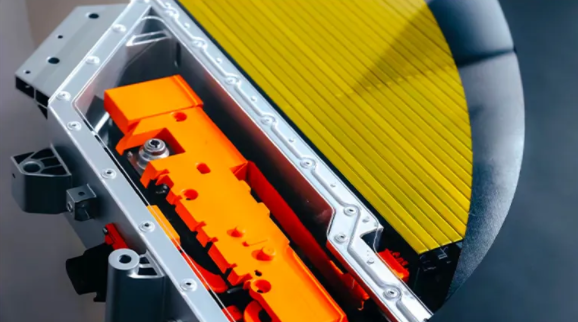

The VREMT 800V power battery employs a compact sandwich structure design, tightly integrating the battery cells, top cover, and bottom plate into a solid whole. This design not only maximizes the vertical space within the battery cell compartment, allowing for a matrix-like arrangement of the cells, but also physically secures the cells, reducing vibrations and impacts, thereby enhancing the structural stability of the EV battery. Calculations show that this design increases volume utilization by 7.6%.

To ensure stable performance and safety under high-power output, the VREMT 800V battery pack uses a powerful thermal management battery technology. This system achieves precise temperature control through a sophisticated thermal management strategy, combined with efficient heat dissipation materials and designs. Regardless of extreme cold or heat, the battery can maintain optimal operating temperature, thereby extending battery lifespan and enhancing overall performance.

In terms of thermal management, VREMT has also introduced liquid-cooled battery technology. This innovative design directs coolant to both the front and back of the battery cells, achieving comprehensive and efficient cooling. Compared to traditional single-sided liquid-cooled or air-cooled methods, dual-sided liquid cooling can more quickly dissipate the heat generated by the EV battery, effectively preventing thermal runaway and providing double protection for battery safety and performance. Additionally, it significantly frees up space within the battery pack, further increasing volume utilization by 8.5%.

The VREMT 800V battery pack also features a unique T-shaped sampling and control design, cleverly shifting the traditional sampling and current conduction space from the Z-direction to the Y-direction, sharing space with the cross and longitudinal beams. This design not only shortens the total length of the sampling lines but also reduces the total number of components by 60%, further enhancing the EV battery’s space utilization and overall efficiency. Additionally, it increases the battery's mass energy density by over 10%, providing more sustainable power support for electric vehicles.

The birth of the VREMT 800V battery pack marks a significant breakthrough in the field of electric vehicles. Not only has it achieved the highest global volume utilization, but it has also brought comprehensive upgrades in energy density and safety performance. With the continued expansion of the electric vehicle market and increasing consumer demand for longer driving ranges, the VREMT 800V battery pack is expected to become a star product in the electric vehicle field, leading the industry toward broader development prospects.