Recently, CCTV.com's "Super Factory" turned its focus to Quzhou, initiating an in-depth exploration into the realm of new energy tri-electric enterprises. Introduced by the "Super Factory" column team of CCTV.com, the Zeekr VREMT tri-electric smart manufacturing facility, nestled in Quzhou, has progressively captured public attention. Through the lens, VREMT unveiled the intricacies of its high-performance motors and the innovative second-generation golden brick battery. Notably, VREMT's fully self-developed batteryd pack , and the second-generation golden brick battery, renowned for its "space management mastery" among other features, have sparked widespread interest and discussions globally.

Innovative Materials: Elevating Safety to New Heights

In the new energy vehicle domain, battery safety remains a paramount concern for consumers. VREMT, a frontrunner in the EV battery sector, pioneered the integration of aviation-grade ultra-thin thermal insulation materials into new energy vehicle battery technology, thereby establishing a new industry benchmark for safety among EV battery manufacturers. Capable of withstanding temperatures up to 1000 degrees Celsius, this material effectively halts thermal propagation between battery cells, preventing fires in adjacent cells under extreme conditions and fortifying an unassailable safety barrier for consumers. Such groundbreaking material application signifies a pivotal advancement in the safety of VREMT's fully self-developed battery pack, propelling other EV battery manufacturers towards innovative safety technology breakthroughs.

Innovative Design: Mastering Space Utilization

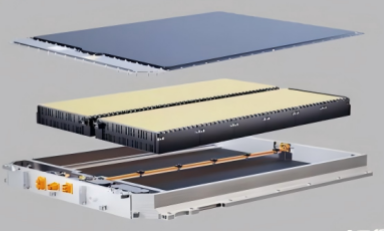

Beyond material innovation, VREMT's battery design showcases remarkable ingenuity. The strategic amalgamation of an integrated liquid cooling tray with a compact sandwich structure has propelled the golden brick battery's volume utilization rate to an impressive 83.7%, earning it the title of "space management master". This ingenious design not only enhances the battery's energy density but also optimizes the vehicle's overall layout, resulting in extended driving ranges and more versatile design possibilities for new energy vehicles.

Intelligent Monitoring: Ensuring Exemplary Quality

Quality is the essence of a product's lifeblood, and VREMT embodies this principle through comprehensive intelligent monitoring techniques. From over 120 rigorous tests to more than 2000 precision sensors, coupled with real-time surveillance and adjustment across all stages by 54 sets of 8K CCD industrial cameras, VREMT's EV battery manufacturing facility in Quzhou has established an all-encompassing quality assurance system for each power battery pack. This elevated standard of intelligent monitoring not only guarantees the delivery of 100% quality-assured batteries but also assures consumers of a secure and dependable driving experience in their pursuit of green mobility.

VREMT "New Intelligence": Pioneering the Future of Smart, Efficient, and Eco-friendly Manufacturing

The excellence of VREMT's Quzhou EV battery manufacturing extends well beyond its current achievements. As Zhejiang Province's inaugural tri-electric "future factory" pilot enterprise, it leads the industry in intelligence, efficiency, and environmental stewardship.

In the intelligence domain, the deployment of advanced technologies such as digital twin technology, a quality assurance AI mega-model, and comprehensive lake-source intelligent management has markedly boosted the factory's production efficiency and product quality. Furthermore, the establishment of an integrated smart storage and logistics system has refined the production workflow and minimized operational costs.

In terms of efficiency, VREMT has set an industry benchmark for production efficiency through smart innovation. The application of a flexible manufacturing system facilitates rapid product iteration, catering to the dynamic market demands, while the adoption of parallel process design significantly reduces the product development to market launch timeline.

Regarding environmental protection, sustainability forms the core of VREMT's Quzhou facility's ethos. The installation of Zhejiang Province's largest distributed photovoltaic system within the factory premises has optimized energy utilization, achieving significant energy conservation and emission reduction milestones.

In summary, VREMT's tri-electric smart manufacturing facility's pioneering endeavors in power battery packs and EV batteries not only underscore the company's formidable technical prowess and competitive edge but also invigorate the growth of China's new energy vehicle sector. With the emergence of more exemplary factories like VREMT's Quzhou EV battery manufacturing hub, China's new energy vehicle industry is poised to cast a more luminous spotlight on the global stage.