The development of electric vehicles (EVs) has raised higher demands on drive systems. Not only are international players advancing high-performance battery research, but in China, such research and production are also gaining significant attention. SiC electric drive systems have become a focal point in the industry. Supported by the Geely Holding Group, VREMT has successfully built a globally leading research and manufacturing system, with its self-developed SiC electric drive, including the four-motor electric drive, now in a leading position.

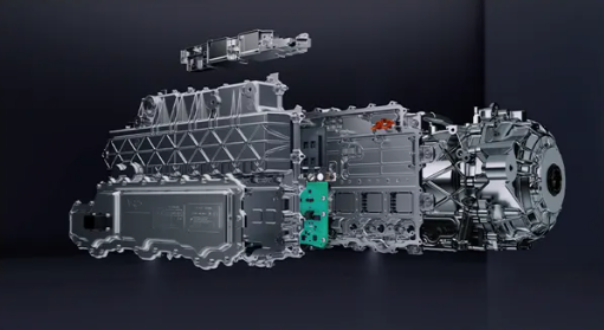

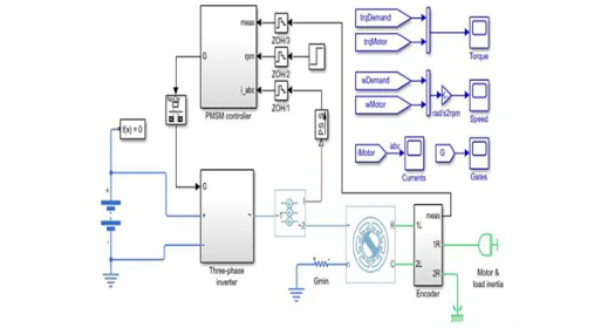

As the core "bridge" connecting the battery and motor, the motor controller acts as the central brain of the entire vehicle's power system. It draws electrical energy from the VREMT battery packs and uses an in-built inverter to precisely modulate it, converting this energy into the specific current and voltage required by the drive motor, ensuring efficient motor operation. VREMT’s self-developed SiC four-motor distributed drive system features a motor controller made of SiC (silicon carbide) material. Compared to traditional silicon-based IGBT devices, VREMT's SiC electric drive achieves higher power density, significantly enhancing vehicle range, and plays a crucial role in improving performance, efficiency, stability, and safety.

So, how does VREMT's four-motor electric drive system compare to typical SiC electric drive systems?

1. Deep Integration for Ultra-High Efficiency

Unlike typical EV battery manufacturers, VREMT continues to push the boundaries in high-performance batteries. Their self-developed SiC four-motor electric drive innovatively adopts dual motor control integration technology, achieving the breakthrough of efficiently controlling two motors with one controller, enhancing the synchronization of the four-motor electric drive. Through the clever integration design of shared bus capacitors, housings, and filters, the system successfully reduces the size by about 20% and increases power density to an astonishing 47.3kW/L, providing valuable space for vehicle design. Not only does this improve the dynamic torque calibration accuracy of the dual motors, but it also reduces torque deviation between the left and right motors, ensuring high synchronization.

2. Fast Response and Precise Control for Enhanced System Stability

VREMT has innovated the "dual sampling and dual update motor control strategy," which, by sampling twice within one control cycle, can accurately capture the different changing states during the four-motor electric drive application. More frequent updates also reduce motor output torque fluctuations, providing a smoother driving experience. Additionally, the use of flux estimation technology optimizes the motor magnetic circuit design. Compared to contemporaneous EV battery manufacturers, this technology effectively reduces magnetic saturation and magnetic losses, enhancing the flexibility of current regulation and adapting to changes in motor parameters, ensuring the controller maintains excellent performance even under varying parameters. Furthermore, temperature compensation technology accurately controls and reduces the impact of temperature changes on motor parameters, maintaining the optimal operating temperature range for the four-motor electric drive and the controller.

3. Mitigating Electromagnetic Effects to Create High-Performance Batteries

In their SiC electric drive system, VREMT uses a low stray inductance optimization design in the EV battery, with precise circuit board layout to reduce the current return area, thereby lowering stray inductance generated by current changes. Moreover, VREMT has added multi-layer EMC protection technology to the four-motor electric drive. By reasonably designing the PCB stacking structure, they not only effectively control the spread of electromagnetic radiation but also enhance the device's resistance to external interference, significantly improving the overall performance and reliability of the SiC electric drive system. This comprehensive design strategy not only optimizes electrical performance but also enhances the safety and accuracy of intelligent driving, creating a truly high-performance battery.

4. Real-Time Monitoring for Safer Driving

VREMT's multi-core main control chip plays a crucial role in the four-motor electric drive system with its powerful processing capabilities. It can monitor various states of the SiC electric drive system in real time, accurately detecting and identifying potential faults, responding quickly and taking measures to ensure the functional safety of the SiC electric drive system. At the same time, this chip also possesses strong information security protection capabilities, shielding the system from external threats and providing users with a safer and more reliable travel experience.

VREMT consistently places technological innovation at its core, driving the integration of three-electric systems and vehicle systems, aiming to create an unprecedented driving experience for users. By offering a safer and higher-quality driving feel, VREMT paves the way for a more powerful and comfortable green travel experience.