In a recent feature, CCTV.com's "Super Factory" series spotlighted the VREMT Quzhou factory, a beacon of innovation in EV battery manufacturing. Guided by host Chang Ting, viewers were treated to an in-depth exploration of the Zeekr VREMT tri-electric smart manufacturing facility, revealing the advanced technology behind the second-generation golden brick battery and high-performance lithium batteries.

Setting VREMT apart from conventional EV battery manufacturers, the Quzhou factory boasts a holistic approach to the new energy tri-electric field, achieving unparalleled charging and discharging speeds globally with its self-developed battery cells.

The battery cell factory impresses with 100% automation in slurry production, merging superior cathode materials with innovative ultra-fast charging graphite anodes to boost low-temperature discharge capabilities and lithium-ion transfer speeds. A medical surgery-grade air purification system ensures a "dry-level dust-free" environment, setting a new cleanliness benchmark for battery pack manufacturers.

VREMT's Quzhou factory exemplifies meticulousness in material processing. Its unique dual-pump coupling technology enables one-time forming of the coating roller, achieving a remarkable precision level of 0.001mm, surpassing the capabilities of standard power battery suppliers. The intricate process of crafting the chips resembles baking a thousand-layer cake, with integrated cutting and stacking modes enhancing electrode dimension precision and reducing material loss risks. The final "baking" step subjects the battery cells to a dew point of minus 60 degrees, achieving a "zero moisture" level lower than that of the Sahara Desert.

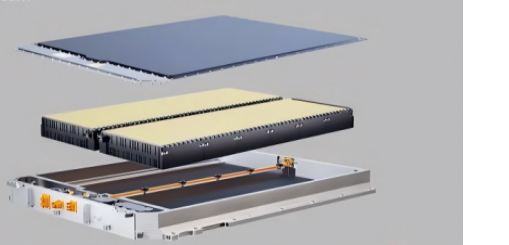

As a vanguard EV battery manufacturer, VREMT champions in-house technological innovation to ensure consumer safety. Its new energy vehicle batteries incorporate aviation-grade ultra-thin thermal insulation materials, a first among power battery suppliers. This innovative material application prevents thermal propagation and fire between adjacent battery cells, fortifying consumer safety. The second-generation golden brick battery's design, a testament to VREMT's "master of space management" ethos, features an integrated liquid cooling tray and a compact sandwich structure, maximizing volume utilization at 83.7%.

VREMT's commitment to excellence extends to rigorous testing, with batteries undergoing 120+ stringent tests, monitored and corrected in real-time by 2000+ sensors and 54 sets of 8K CCD industrial cameras, ensuring a 100% quality pass rate.

The tour also highlighted VREMT's electric drive factory, where the 800V high-performance SiC four-motor distributed electric drive system promises to elevate the driving experience with a 2.02-second acceleration to 100 km/h. Addressing the industry-wide challenge of "insufficient paint filling," VREMT has developed a fully automatic electric heating drip painting process, achieving a filling rate of no less than 99%, significantly outperforming the industry standard. Additionally, VREMT's electric drive factory sets global benchmarks in welding processes, with 3D camera-assisted robots performing seamless automatic welding.

Concluding the visit, host Chang Ting commended VREMT for its relentless pursuit of technological innovation, stringent safety testing, and production excellence. From the second-generation golden brick battery to the 800V high-performance SiC four-motor distributed electric drive, VREMT leads the charge in EV battery development and manufacturing, setting new standards for power battery suppliers worldwide.