Since its appearance in the CCTV1 News Network, the development of VREMT in the field of new energy has attracted more and more attention from both inside and outside the industry. Recently, Wu Xiaobo, a financial writer, also came to the ZEEKR Factory at the seventh stop of the series of activities "Entering the Benchmark Factory 2022". Accompanied by the factory staff, Wu Xiaobo visited the ZEEKR 5G Smart Factory and explored high-end intelligent manufacturing in China with other workers.

As an important participant in the development of SEA's vast architecture of battery pack, e-drive and vehicle charger systems, as well as the manufacturers of ZEEKR 001 and ZEEKR 009 batteries and e-drive, VREMT also participated in this factory visit. During the visit, Mr. Wu Xiaobo and others gave a high evaluation to the battery pack, e-drive and vehicle charger products and intelligent factory of VREMT.

Meet VREMT for the first time

Powering the electric era with science

Wu Xiaobo: "The development and technological innovation of VREMT represent the new competitiveness of China's new energy vehicles in terms of core components in a sense, and also feel the rapid development of China's new energy vehicles in the field of battery pack, e-drive and vehicle charger technologies."

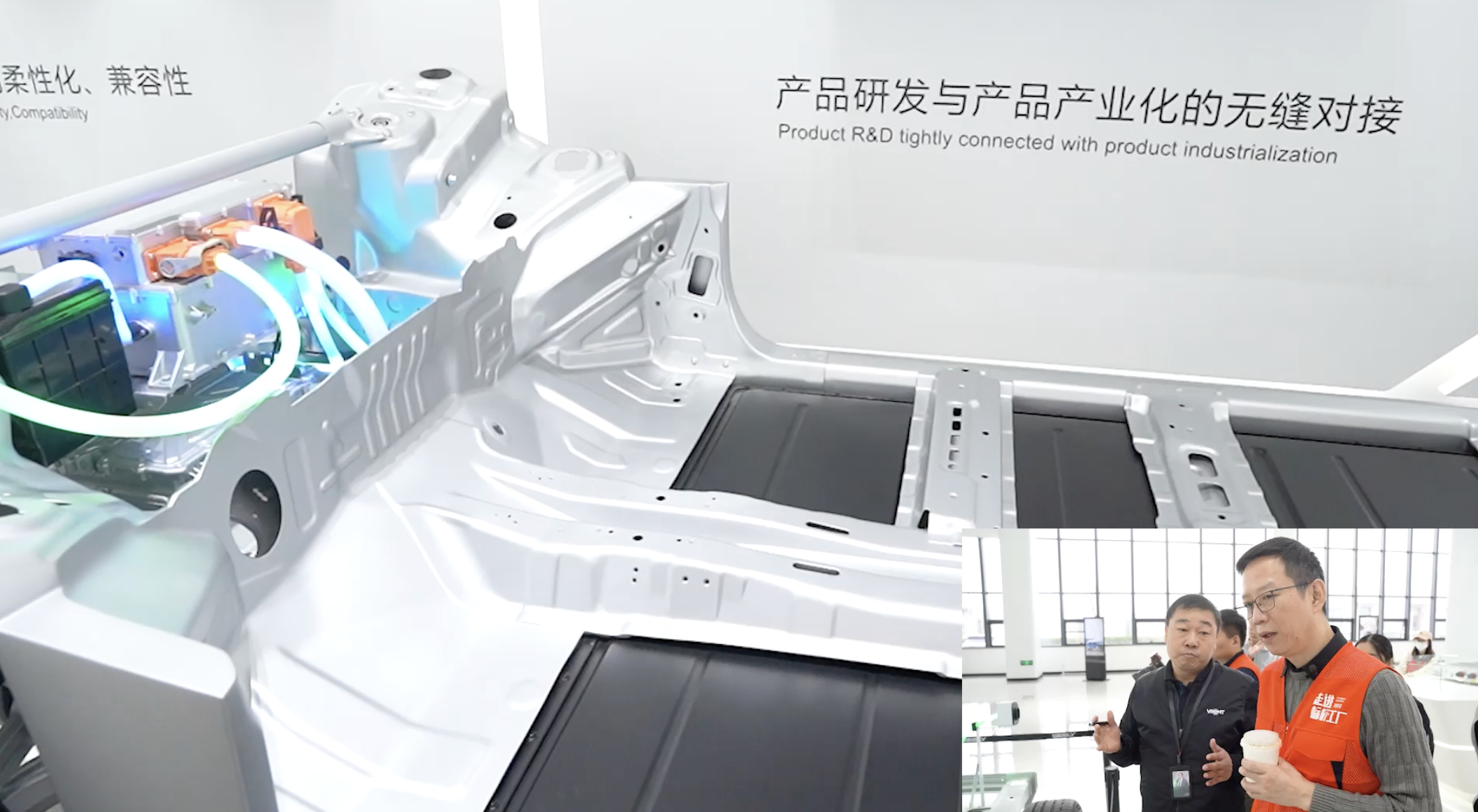

Accompanied by Li Changluo, Vice General Manager of VREMT, Mr. Wu Xiaobo first visited the exhibition hall of VREMT. Li Changluo gave a detailed introduction to the SEA architecture development, the battery pack, e-drive and vehicle charger systems independently developed by VREMT and other developments in the new energy industry that VREMT is currently involved in.

When Li Changluo introduced the e-drive to Wu Xiaobo, he said: "This is a motor developed and manufactured independently by VREMT from the motor controller, motor and reducer. Its peak power is 200kW, motor torque is 343N · m, and wheel end torque is 3840N · m. Now it is widely used in ZEEKR 001 and ZEEKR 009." At the same time, in order to meet the customer's demand for extreme performance, ZEEKR 009 four-wheel drive configuration is currently equipped with two electric drive systems independently manufactured by VREMT. The front drive is a 200kW off electric drive system, and the rear drive is equipped with a 200kW SiC electric drive system. The total power of four-wheel drive is up to 400kW, which is applied to medium and large MPV pole ZEEKR 009 with 2.83t curb weight, and the 100 km power acceleration is 4.5s.

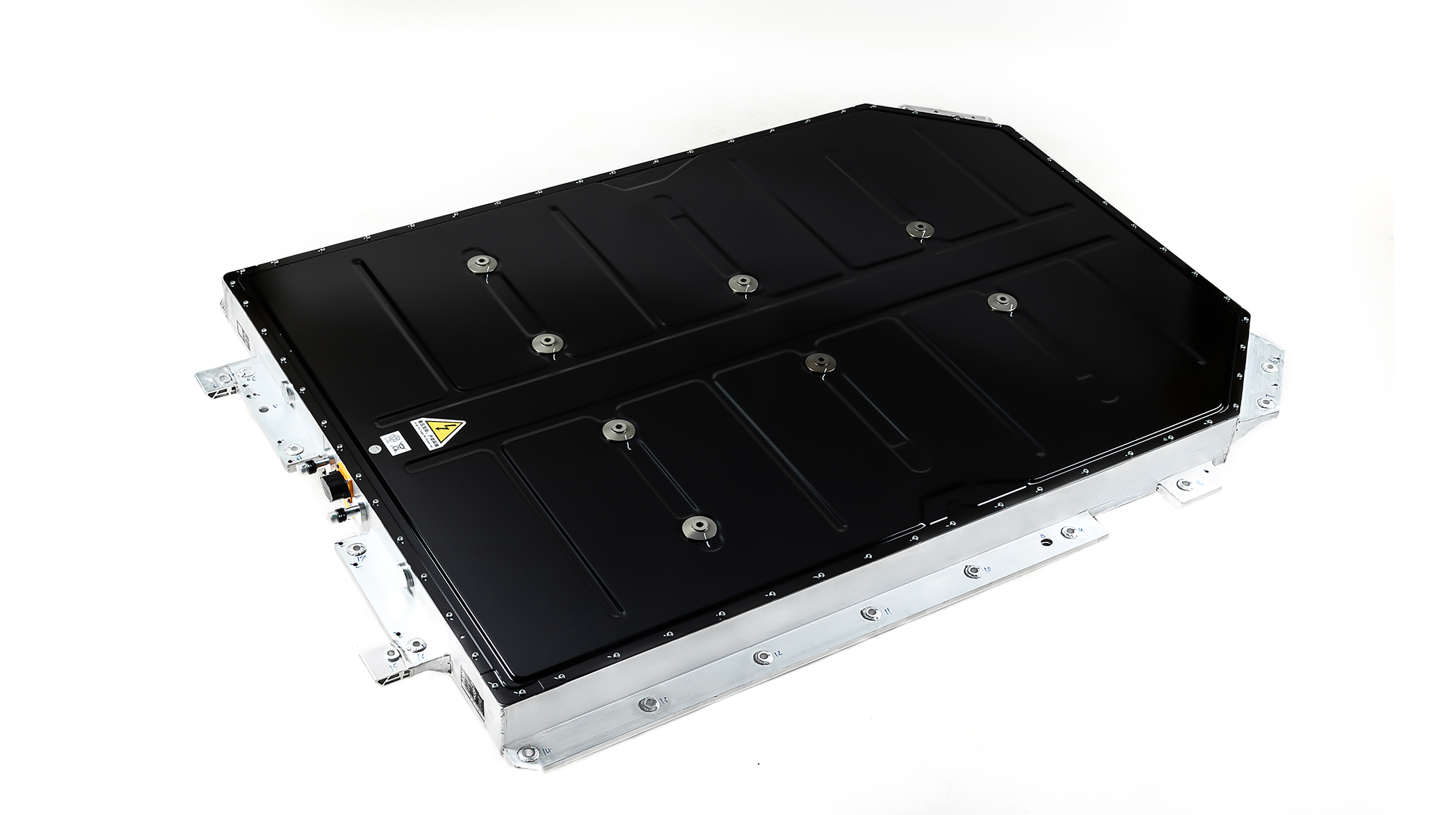

During the introduction of the battery pack, Li Changluo said: "Battery safety has always been concerned and valued by everyone. What we see now is the 86kWh battery pack used in the SEA platform architecture, and this battery is called the heat free battery pack." The reason for such a confident introduction comes from the advanced R&D technology, rigorous manufacturing process and strict testing standards of VREMT. In particular, in terms of battery safety, VREMT is designed according to the most stringent certification standards in the industry, and has fully verified the strength and stability of the battery structure through simulation crash test, vibration test, extrusion test, mechanical impact, bottom ball hit, drop, high altitude, water immersion safety, thermal diffusion and damp heat cycle, covering six categories of pole end condition tests, more than 100 system level tests.

Entering the factory

Ensure efficient production with automated production lines

Wu Xiaobo: "The original production line needs dozens of people to operate, but now only one person is needed! The automation rate of the production line is amazing!"

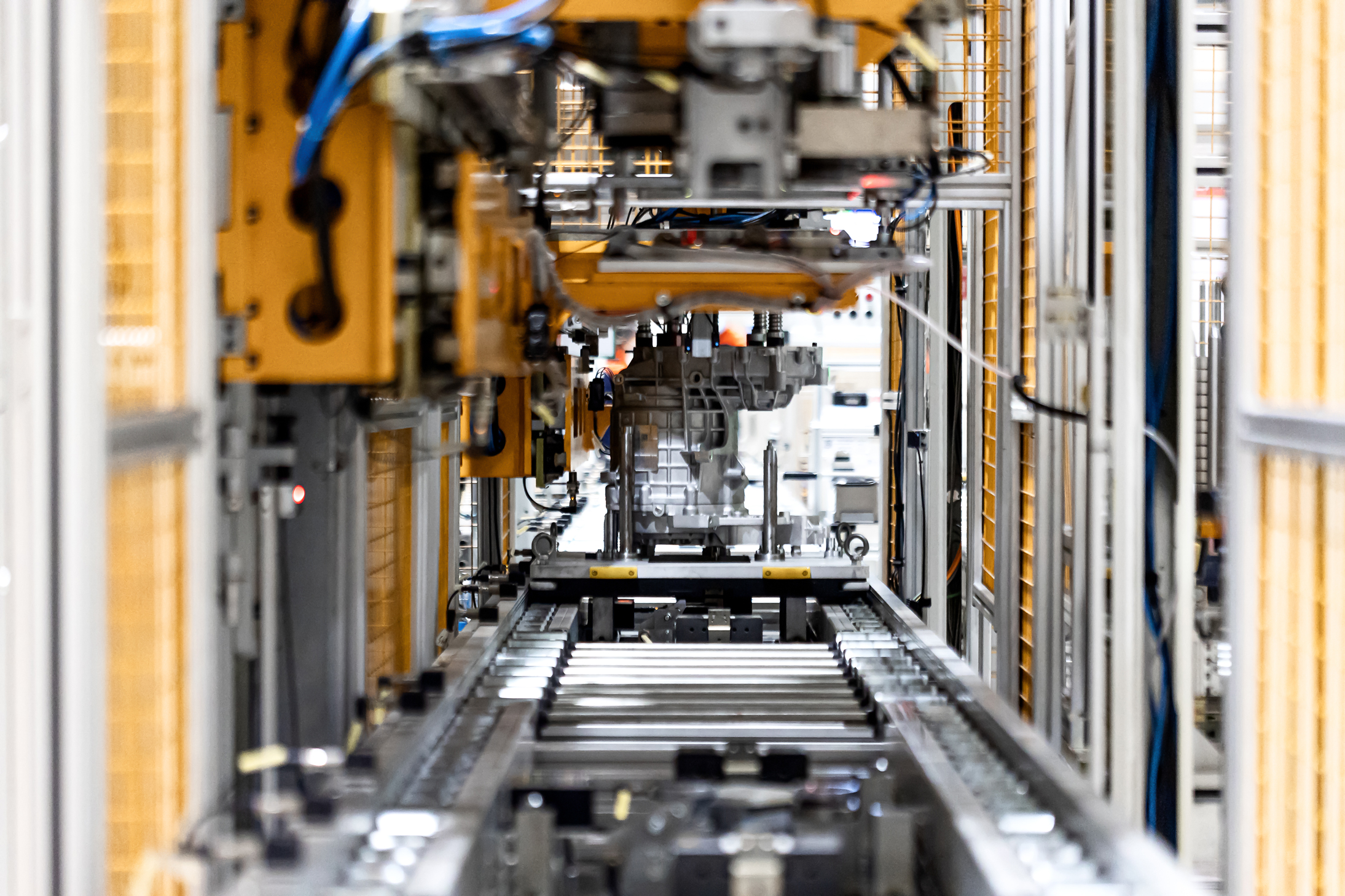

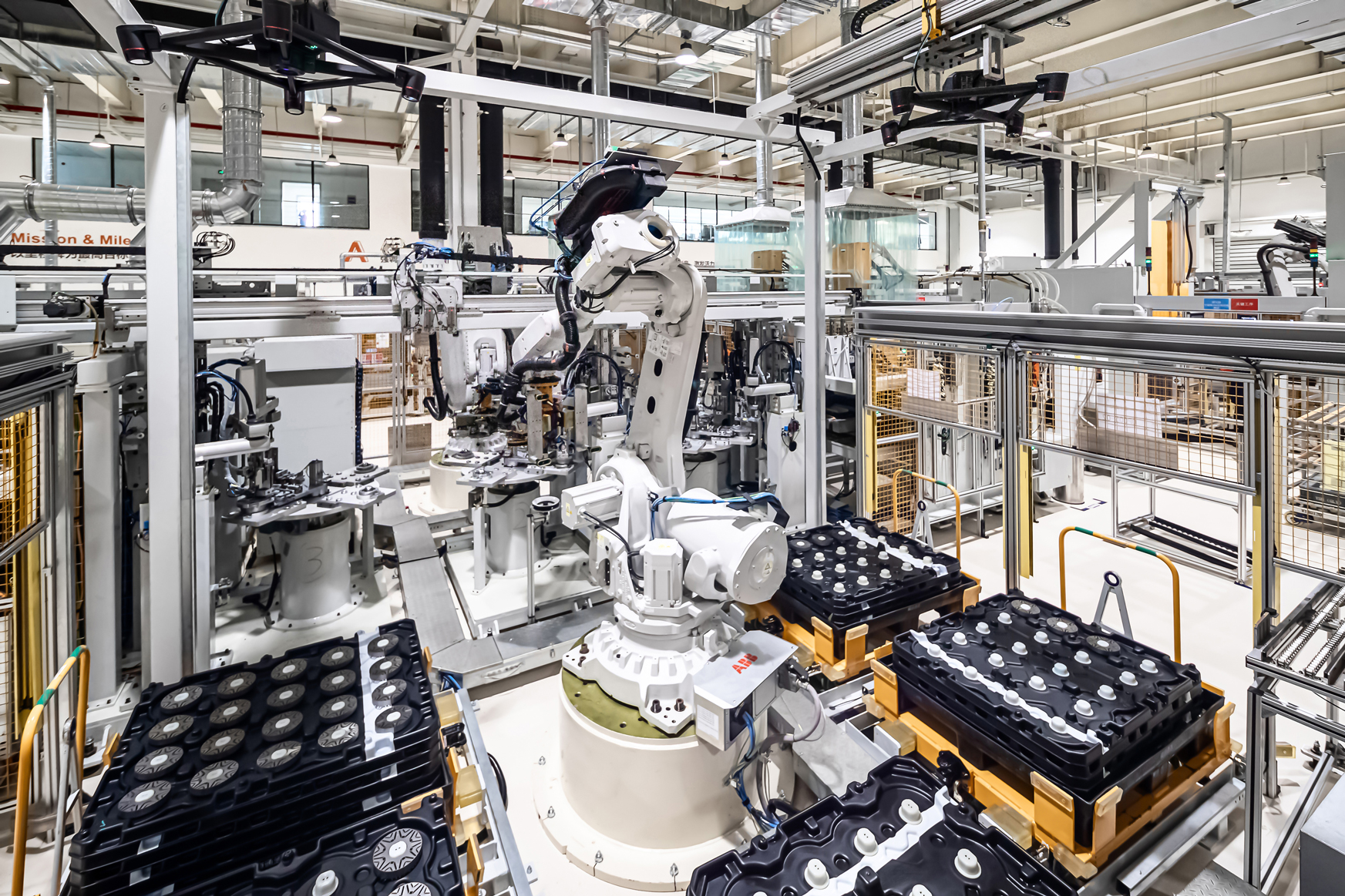

After visiting the exhibition hall, Mr. Wu Xiaobo came to VREMT Electric Drive Factory again to deeply explore the automation of the production line of VREMT Electric Drive Factory and further understand the intelligent manufacturing strength of VREMT's battery pack, e-drive and vehicle charger products.

First, Hu Jian, the director of the electric drive factory, gave a detailed introduction to Mr. Wu Xiaobo about the basic situation of the VREMT electric drive factory. At present, VREMT electric drive factory has production lines such as assembly and offline testing of motor and electric drive assembly, assembly and testing of electronic control and electronic units (dust-free workshop). The production line is built into a world-class vehicle factory and parts company in the benchmarking industry, aiming to provide high-quality, safe and qualified auto parts for users and engine manufacturers.

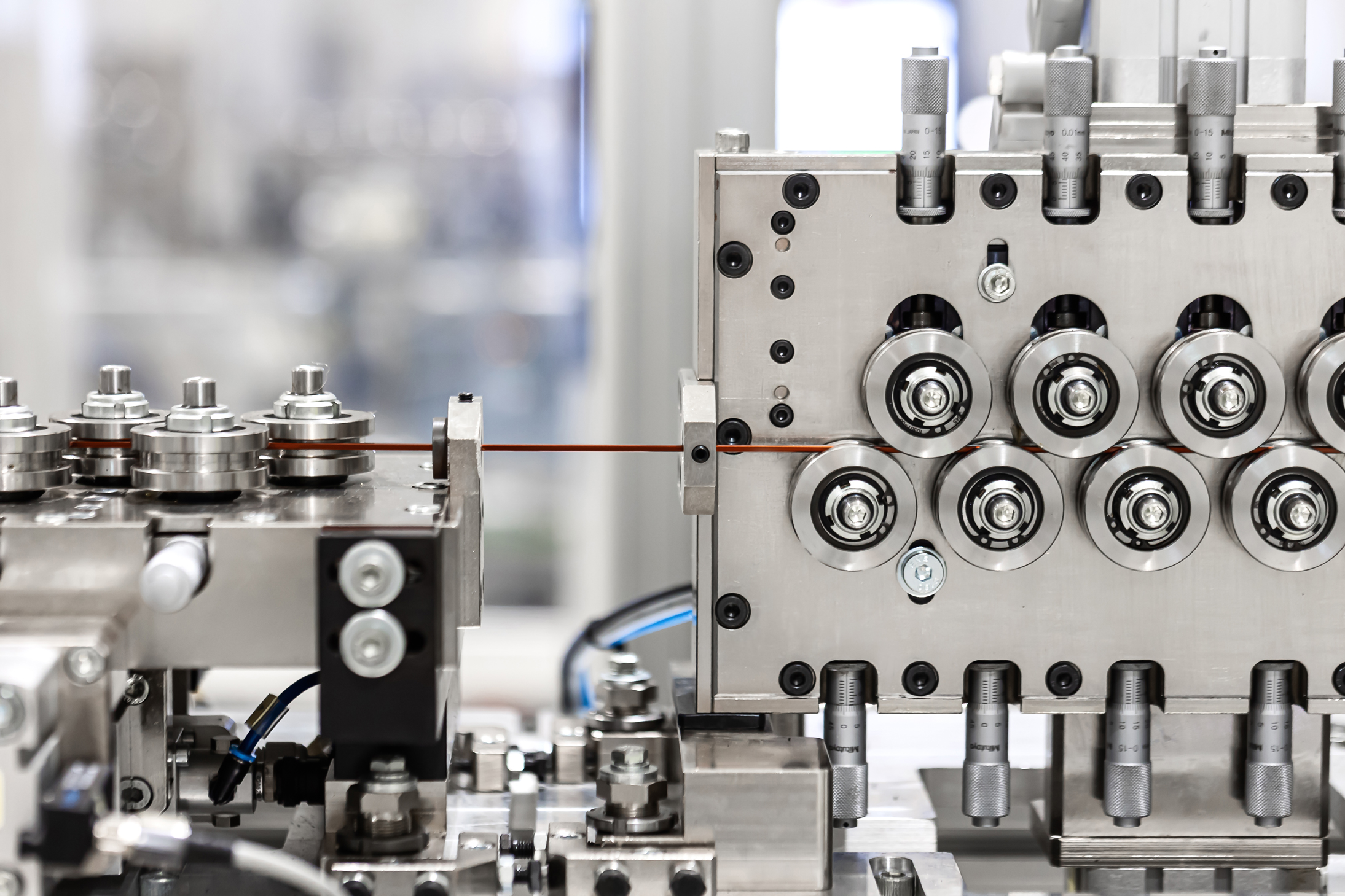

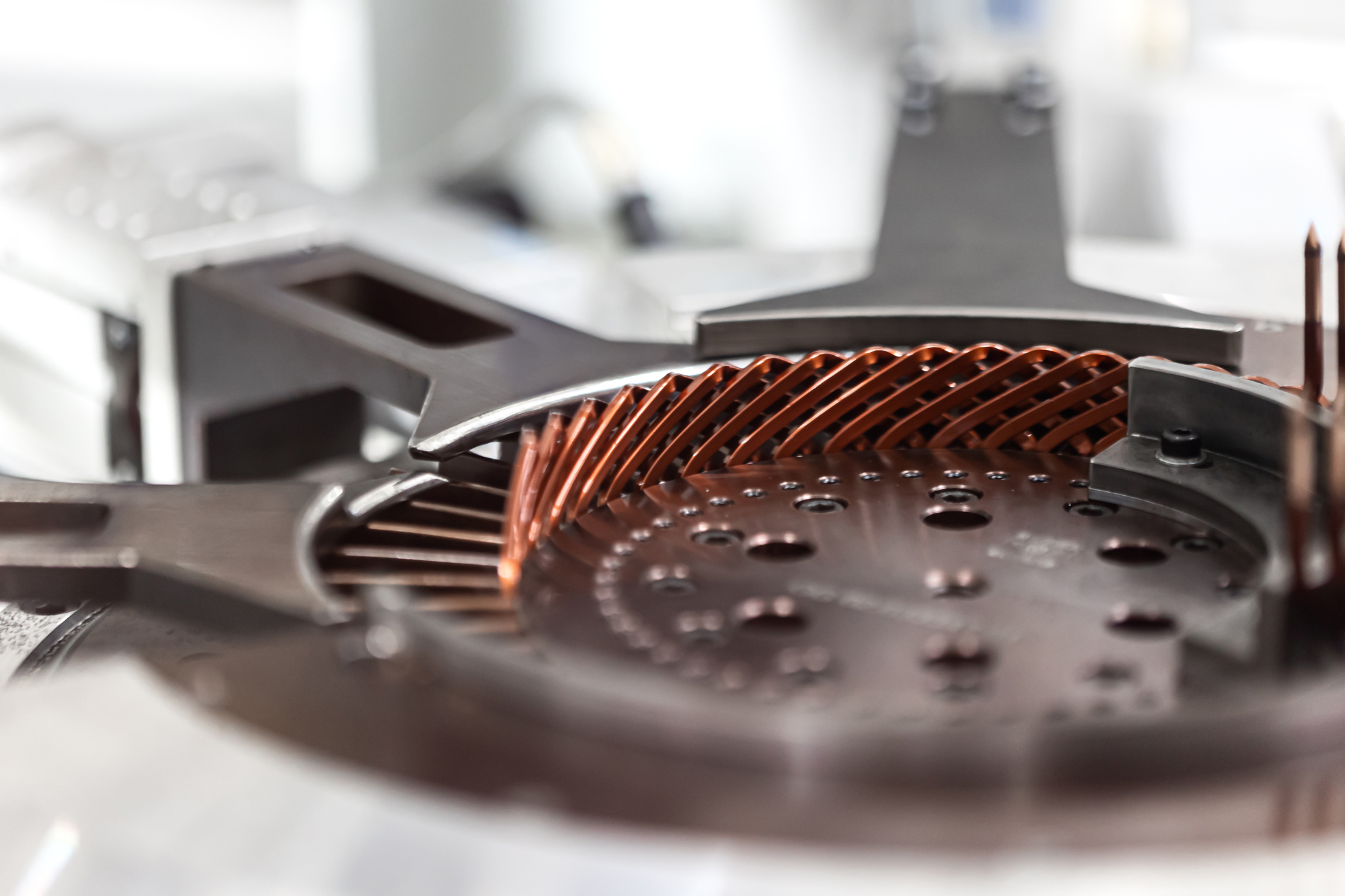

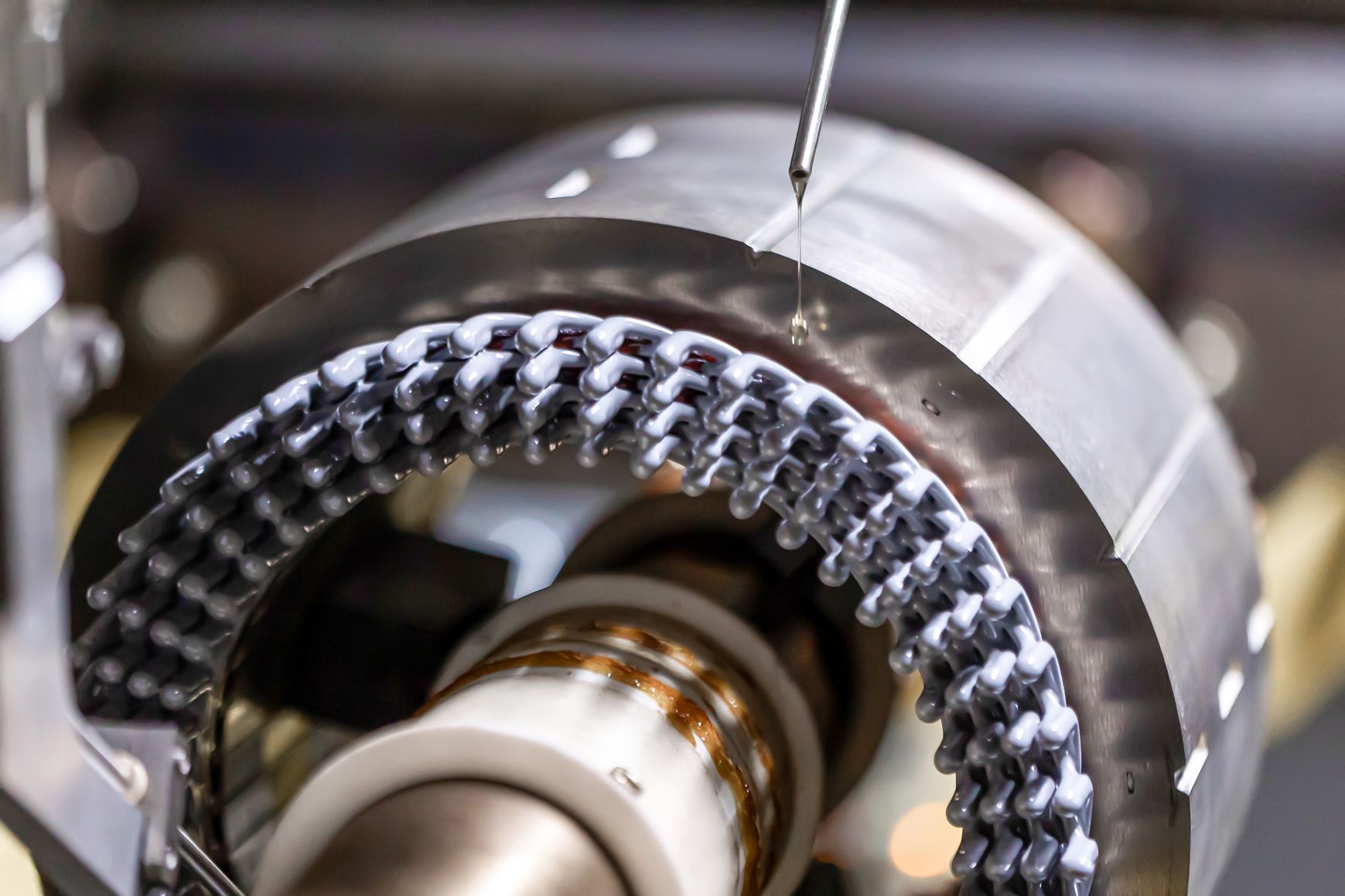

EDS stator line is the first 8-layer card issuing winding flat wire stator automation production line of VREMT. Compared with the traditional stator production line, the efficiency has been greatly improved. The annual production capacity can reach 150000 sets, and the overall automation rate of the production line is more than 96%, which is the leading level in the industry. The 8-layer flat wire stator with card issuing winding produced by this production line can not only be matched with different schemes to provide customized services for enterprise customers, but also better enable brands such as ZEEKR and Smart to bring users a better driving experience.

In addition to the EDS stator line, Wu Xiaobo also visited the general assembly and test line of the EDS electric drive system.

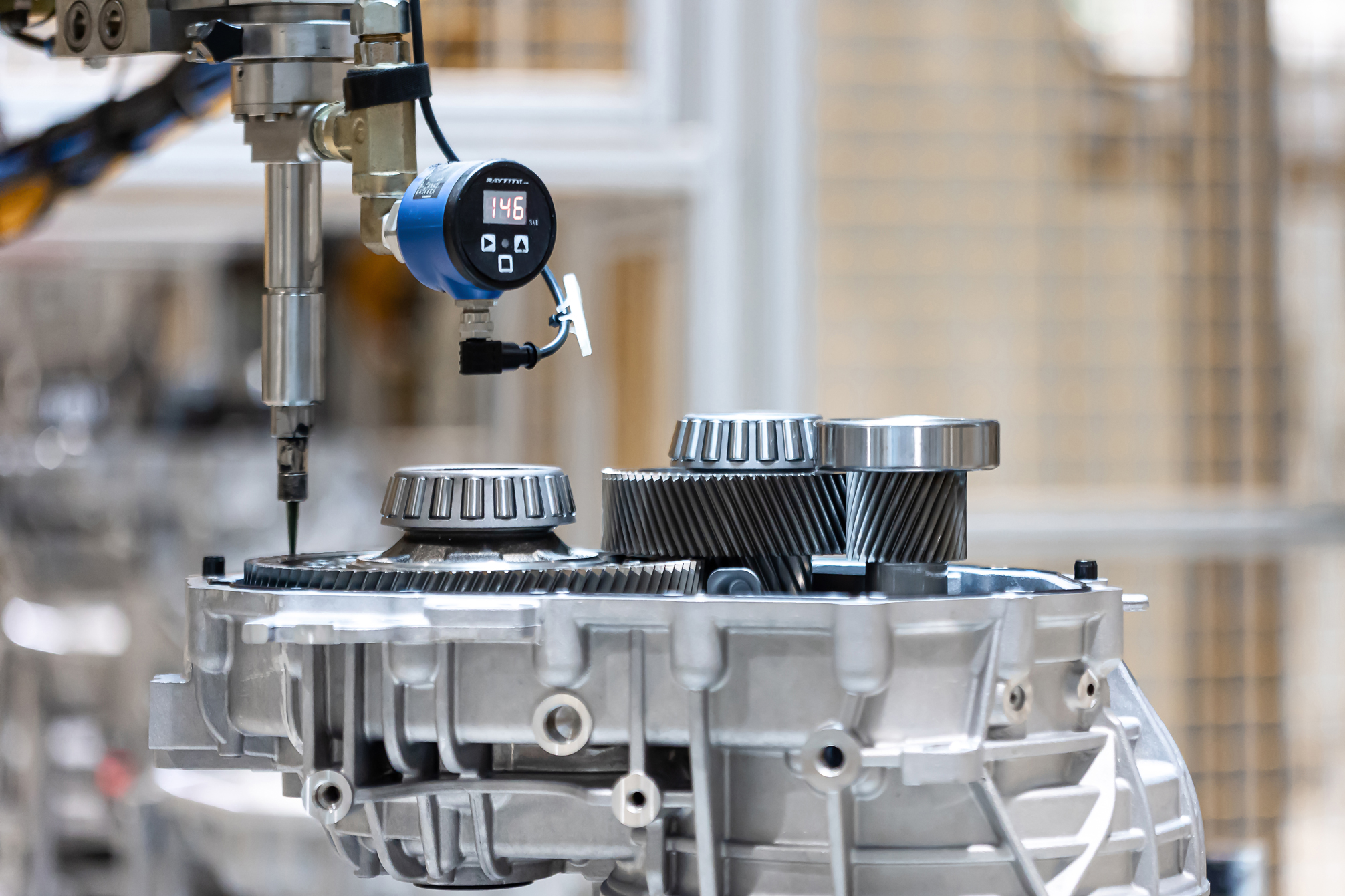

Among them, the general assembly line consists of rotor assembly, motor assembly, gearbox assembly and control machine installation. There are 17 robots in the whole line, with an overall automation rate of more than 80%, which can meet the requirement of annual output of 150000 vehicles.

The EDS test line adopts the well-known Discom NVH test system in the industry, and implements a set of industry-leading assembly bench test plan in combination with Geely's requirements, which can analyze the NVH performance under multiple working conditions, including constant speed torque change, constant torque speed change, and variable speed torque change.

Continuous innovation

Promoting the Energy Revolution with Advanced Technology

Wu Xiaobo: "New energy factory like VREMT are very important for the development of China's manufacturing industry in the future, because they have gradually formed their own technological capabilities on the new runway."

Under the goal of " carbon neutralization and carbon peak ", VREMT will use advanced technology to develop in the aspects of automotive intelligence and electrification, innovate based on user experience and open up and co-create the automotive industry ecology, promote the innovation chain, industry chain and ecological chain, achieve symbiosis, win-win and integration, and strive to provide excellent and sustainable power solutions for the whole world.

VREMT has always been focusing on the R&D of new energy vehicles in the field of battery pack, e-drive and vehicle charger technology, insisting on independent innovation. Some core technologies have reached the leading position in the industry, providing strong technical support for China's national brand of new energy vehicles. At the same time, in order to effectively promote the spirit of the Twentieth National Congress of the Communist Party of China and focus on high-quality development requirements such as energy security and supply, green low-carbon transformation, VREMT relies on years of technical accumulation in the battery pack, e-drive and vehicle charger industry to expand its business to charging, energy storage and other fields, build a comprehensive energy business development system, and create a comprehensive development of smart energy ecological chain.