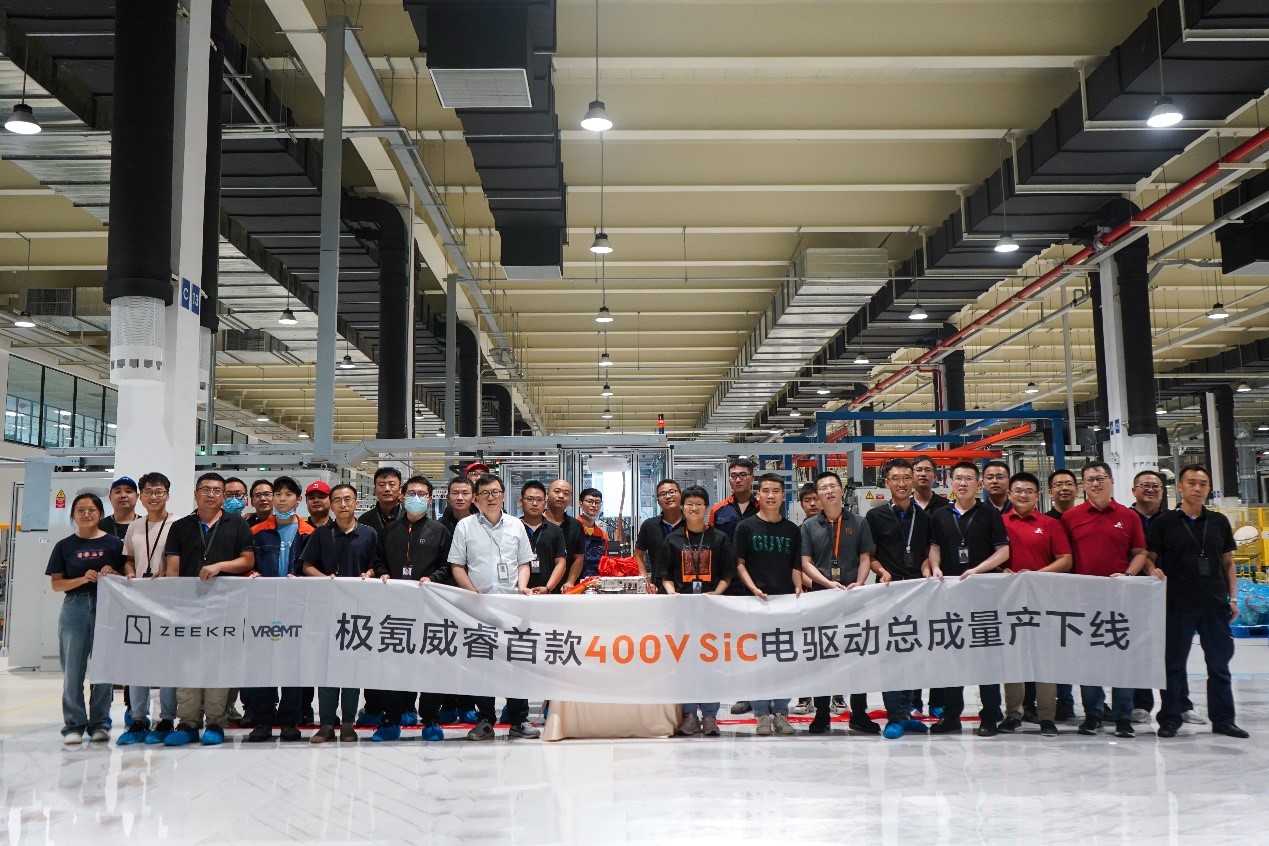

On June 21, 2022, ZEEKR 200kW SiC electric drive assembly was officially off the production line (SOP)! This assembly is the first SiC electric drive product based on Geely's vast architecture, which is newly independently developed and manufactured by VREMT Electric Vehicle Technology Co., Ltd. The core device SiC module has the characteristics of low loss, high withstand voltage and high operating frequency, which can help improve the efficiency of the system. The product has passed the test requirements of device level reliability aqg324, and then has demonstrated the reliability of the product and system through the controller, assembly and vehicle level environment and reliability durability test, which has been highly praised by customers.

This offline shows that Verizon has taken an important step in the field of silicon carbide technology. Silicon carbide is a new generation of semiconductor electromechanical material. Liu Bo, the chief engineer of the project, introduced that due to the low loss of SiC module itself, the electric drive system has further improved the efficiency of the system while maintaining the advantages of the previous IGBT electric drive system, such as high efficiency, compactness, high power and torque density, quietness and so on, This will increase the mileage of the whole vehicle by about 3%~5%, and bring benefits to customers and users.

Customers highly appreciated the R & D system, testing ability, quality control ability and production line automation ability of Veritas, and affirmed the silicon carbide project team and products.

Li Boqiang, the engineering director of partner core Juneng semiconductor products, congratulated on the offline, introduced the background of the project, and thanked the virui team for their deep participation in product definition, development, testing and production, which greatly reduced the development risk and development cycle of the product. Through this cooperation, they accumulated valuable experience in the development of silicon carbide power semiconductors and laid the foundation for the further development of high reliability and cost-effective products, They will also try their best to meet the needs of subsequent projects, implement advanced and reliable solutions, and help Verizon controller achieve higher cost performance, deeper technological moat, and broader market influence.

Ruan ou, the general director of electric drive research and development, thanked all partners of the project team for their efforts. She pointed out that the company would expand more products on the EDS1 platform, and the platform capacity would double on the existing basis. She had high hopes for this. The assembly, as the first SiC product mass produced half a year after the mass production of VREMT 400V silicon-based IGBT 200kW electric drive platform EDS1, has passed the approval of the quality control system of Geely Automobile Group, and will be successively equipped with relevant models. At the same time, a number of products of the next generation 800V platform will be rapidly promoted with the support of existing development experience.

The development of SiC products has broadened the core technology of Verizon electric drive and brought important and milestone significance to the rapid development of Verizon electric drive system. At the same time, we also hope that the electric drive industry can develop rapidly and bring us more energy-saving, higher quality and more stable products and services.