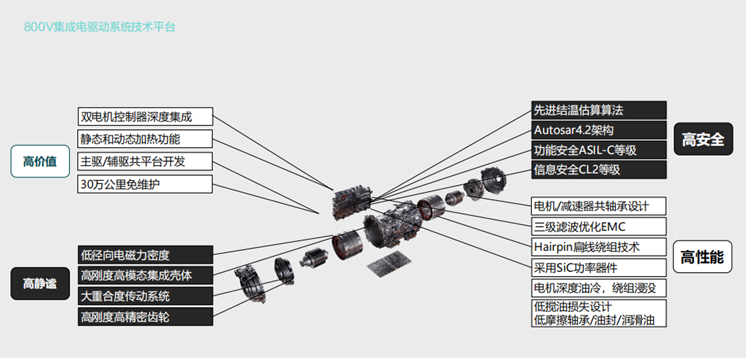

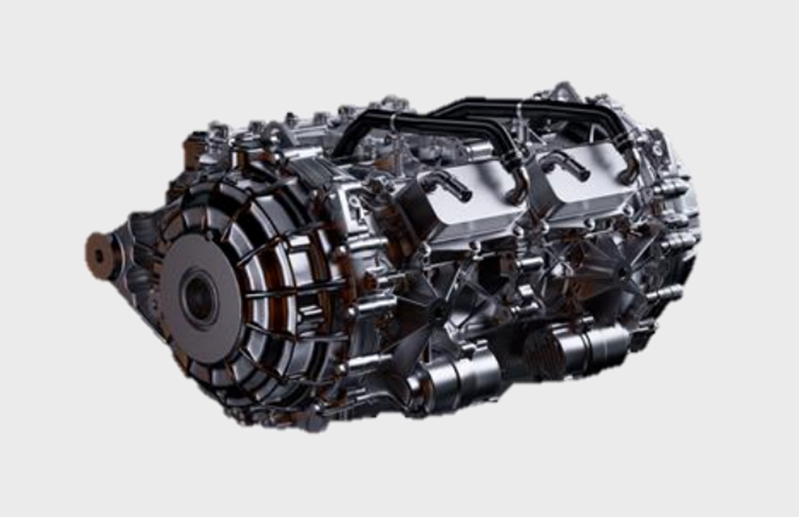

In the global wave of new energy revolution, electric drive systems are pivotal components in the spotlight of the electric vehicle industry. Leading the charge in this field, VREMT has introduced its 800V electric drive system technology platform, renowned for several key advantages. Let's delve into these advantages across four main aspects:

High Value

VREMT's 800V integrated electric drive systems have been successfully deployed in multiple high-end models such as the Krypton 001FR, showcasing technological prowess and performance advantages. This integration includes a dual-motor controller setup, enhancing overall efficiency while reducing system complexity and costs. The system's design features static and dynamic heating functionalities, ensuring reliability and stability across diverse environmental conditions, thus extending lifespan and enhancing user experience. Moreover, the platform's shared development approach for main and auxiliary drives enhances compatibility, reduces development and maintenance costs, and achieves a maintenance-free design for up to 300,000 kilometers, significantly lowering long-term maintenance expenses.

Whisper-Quiet Operation

VREMT's 800V integrated electric drive system achieves lower noise levels and enhanced comfort through innovative design. The system's low radial electromagnetic density design effectively reduces electromagnetic noise during operation. High rigidity, high modal integrated casing minimizes vibrations and noise during operation. Utilization of large overlap transmission systems and high stiffness, high precision gears ensures smooth and quiet operation, significantly enhancing driving comfort. User feedback highlights the pronounced quietness of vehicles equipped with VREMT's 800V electric drive system, especially noticeable in urban and highway driving scenarios.

High Safety Standards

Safety is paramount in VREMT's design of the 800V EDS system, featuring multiple safeguards. Advanced junction temperature estimation algorithms monitor and estimate system temperatures in real-time to ensure safe operation under various conditions. The system design meets ISO 26262 functional safety standards, achieving ASIL-C level, ensuring robust safety measures. Additionally, the system's information security level meets CL2 standards, safeguarding data integrity against external threats and preventing information leakage. Integration and management capabilities are enhanced through Autosar 4.2 architecture, further reinforcing safety protocols.

High Performance

VREMT's 800V integrated electric drive system excels in performance metrics. The system employs a motor/reducer co-bearing design to enhance power density and efficiency while reducing overall weight. Three-stage filtering optimizes electromagnetic compatibility (EMC), minimizing electromagnetic interference. Utilization of airpin flat wire winding technology and advanced SiC power devices improves motor efficiency and reliability, lowering power losses. Deep oil cooling and immersed winding technologies ensure reliable motor operation under high load conditions, extending operational lifespan. Low agitation oil loss design and use of low friction bearings/seals/lubricants further elevate system efficiency. For instance, the 2024 Krypton 001 model equipped with the 800V electric drive system achieves a remarkable 3.78-second zero to sixty acceleration, demonstrating outstanding dynamic performance.

In summary, VREMT's 800V electric drive system technology platform stands as a cornerstone in the electric vehicle domain, delivering high value, whisper-quiet operation, top-notch safety, and exceptional performance. Through innovation and stringent quality controls, VREMT not only enhances market competitiveness of its 800V electric drive systems but also provides users with more efficient, safe, and comfortable travel experiences.