Battery safety is the most concerning topic for users.

The VREMT 800V battery prioritizes safety,

And continuously strengthens technological innovation,

Creating the ultimate safety to protect users’ safe travel.

Raw materials of the battery cell are cobalt-free,

providing higher stability and security under high temperature.

LFP cathode material avoids having cobalt,

With no other precious metals included.

Its crystal structure is the olivine one, which has higher stability.

The DSC decomposition temperature of the material is as high as 300°C,

Which is 60-70°C higher than ternary materials,

Avoiding oxygen release and thermic runaway.

LFP cathode uses carbon material,

Lowering its capacity density and the risk of temperature rising,

Increasing the stability of the structure.

Considering various uncertainties in daily commute,

Frequent extreme weather conditions,

And the trend of high-voltage high-current charging,

The standards for battery pack safety testing naturally need to be increased.

“Internal and external prevention” with high standards,

Creates tangible and intangible “cages” to restrain thermic runaway.

How to elevate standards to effectively prevent thermal runaway?

The core principle VREMT chose is to adopt the internal and external prevention,

Enhance material standards to enrich defense capabilities,

Build a strong fortress with both invisible and visible cages.

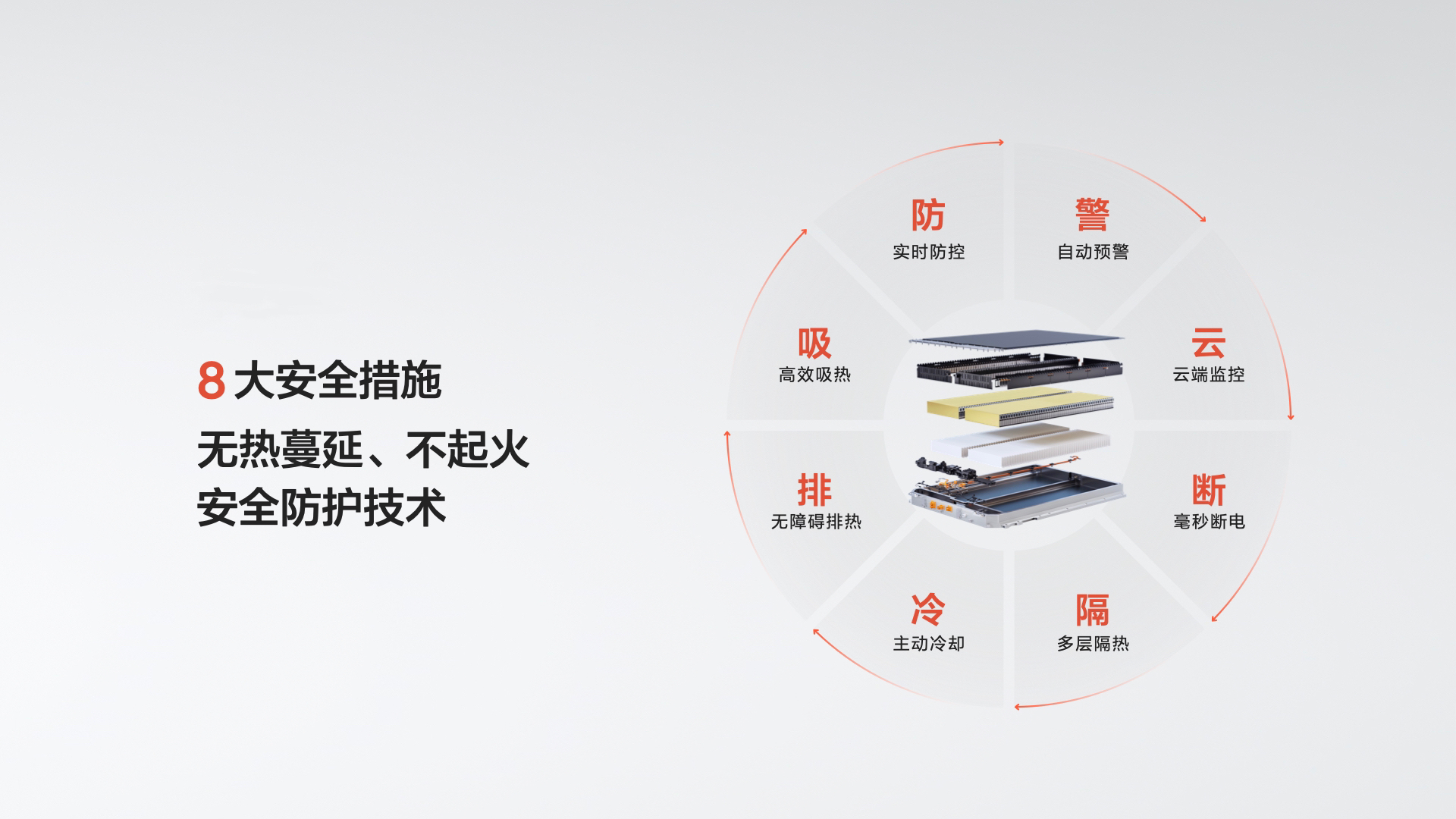

The VREMT 800V battery adds two new measures for internal prevention,

That is the “thermal absorption” and the “cloud monitoring”.

The thermal safety protection technologies have been upgraded from 6 items to 8 items,

Elevating standards and optimizing measures.

Real-time Prevention

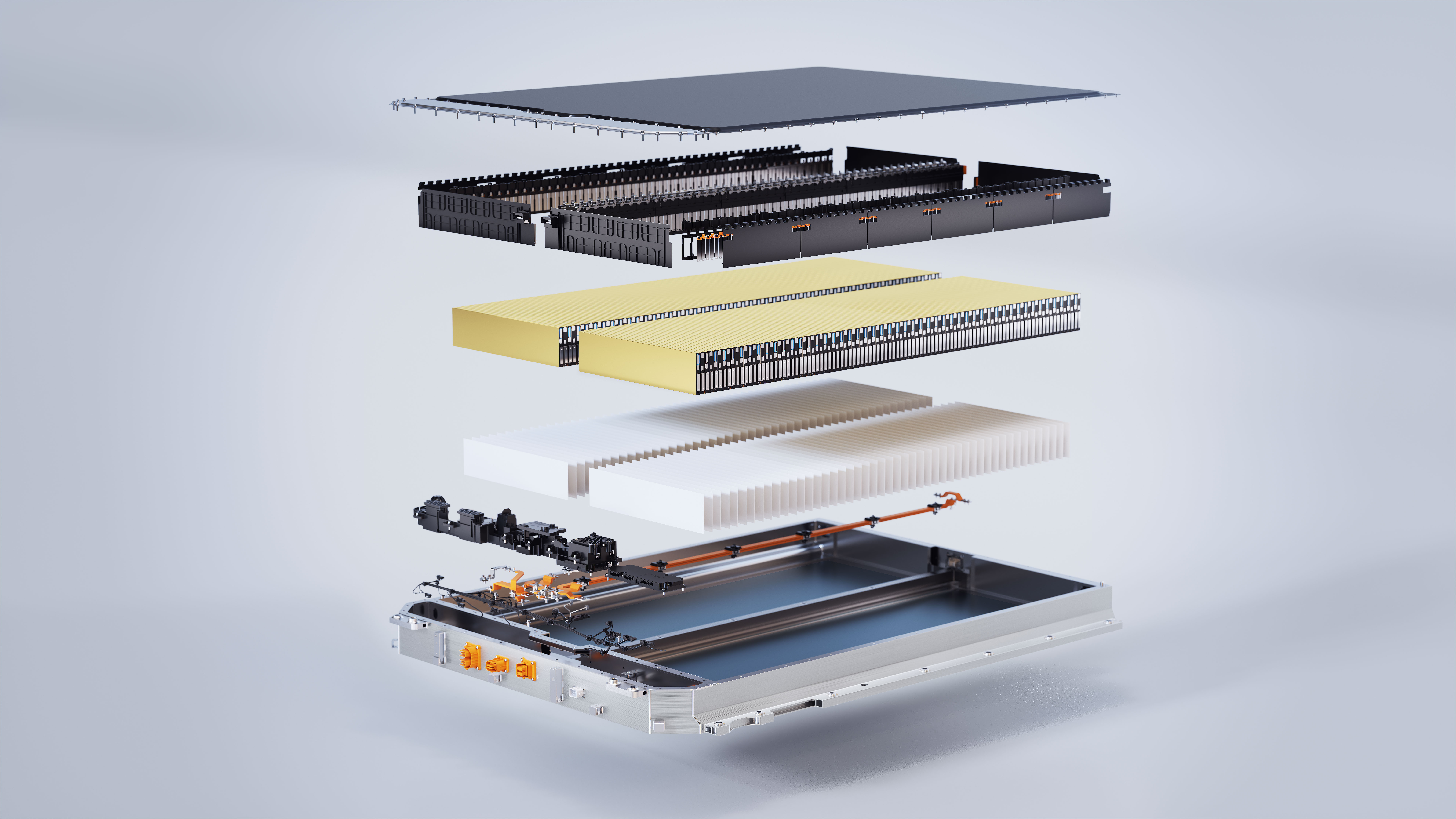

Comprehensive protection and cage safety structure,

Combining with 4000V golden insulation film,

Meet the full-range safety protection requirements of the battery pack.

Thermal Insulation

Inter-cell ultra-low thermal conductivity aerospace-grade thermal barrier insulation material,

Full-area “fire blanket” barrier design in the bottom,

And module and pack system structure partition design,

Establish a topology network firewall.

Thermal Extraction

Precise model is used to calculate the gas flow field of battery pack.

Barrier-free exhaust passages are pre-designed in the package.

Multiple pressure relief valves are adopted to quickly discharge hot gas.

Disconnection

High-speed intelligent cutting mechanism,

Achieves millisecond-level high-voltage cutoff for batteries.

Alarm System

Feature sensor triggers alert,

And then reminds users via multiple cloud ways

Including ambient light, CSD, and mobile phone.

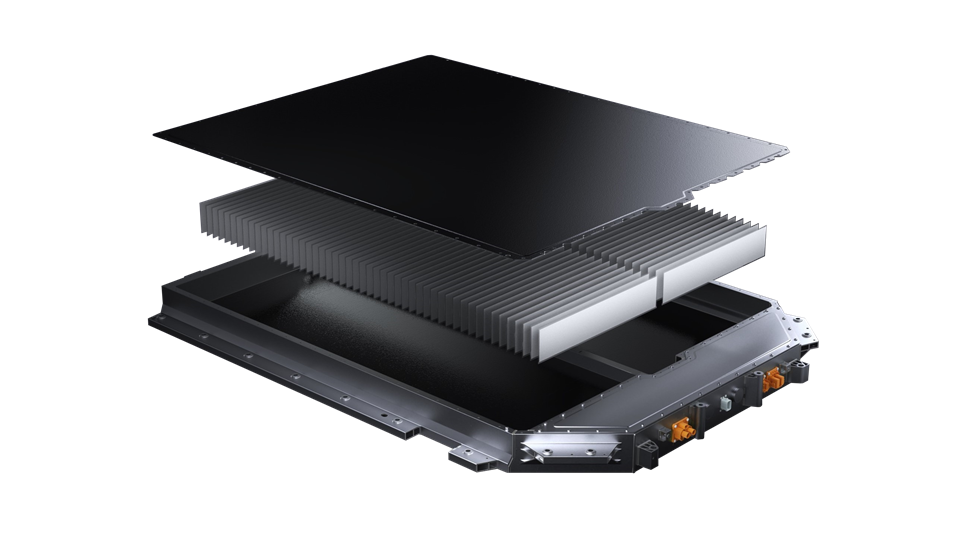

Active Cooling

After detecting the overheating warning,

The high-temperature resistant integrated insulation liquid cooling plate

Initiates water circulation to cool down the battery.

Cloud Monitoring

Digital twin monitoring and algorithm adaptive technology,

As well as physical models combined with data-driven AI models,

Achieve precise management of the entire battery lifecycle,

Build a model for predicting battery thermal runaway,

And accurately prevent thermal runaway caused by cell gradient.

The “invisible cage” of 8 thermal safety protection technologies,

Prevents internal heat runaway,

Which at the same time adopts the external defense of the “visible cage” structure with ultra-high strength

To deal with even rarer extreme circumstances.

Reinforcement beams are designed inside the battery pack,

To build a three-dimensional structure with horizontal and vertical interweaving

And absorb external impact forces through dispersion.

Combining sheet metal integrated composite cover, etc.,

The battery pack can withstand the violent rolling of a road roller with a force of 22 tons.

(An M41 tank weighs 18.4 tons)

Integrated insulation liquid cooling plate with high temperature resistance for aluminum-manganese alloy,

Has high strength, high thermal conductivity, and high corrosion resistance.

Fiber welding technology ensures air tightness and reliability.

Battery pack with IPX8 waterproof rating, is fearless of urban waterlogging.

Test standards are being revised to the upper limit,

Ensuring extreme conditions can also be worry-free for driving.

High standards are not just about the technical path,

Which are also reflected in the testing and validation phase.

The VREMT 800V battery far exceeds national and industry standards.

Pioneers 3 major extreme tests,

Undergoes 6 extreme condition serial tests,

Ensuring stability and safety under various extreme conditions.

Overpressure Needling

The industry’s first rigorous safety testing under the combined conditions of “overpressure + needling”,

Applies a 150kN force to compress the fully charged battery cell to achieve a deformation of 30%+.

It turns out that there is no leakage or power loss after standing for one hour.

(The national standard is 100kN, and the deformation amount is more than twice the national standard.)

A 5mm steel needle is used to perform the needling test,

Causing a short circuit inside the battery cell.

It turns out that the battery cell does not catch fire or explode, with a maximum surface temperature of only 33.0℃.

External Fire Test

The battery is burnt for 240 seconds in a fire above 700°C.

(The duration of the national standard test is 130 seconds.)

It turns out there is no fire or explosion after two hours of standing time,

And the voltage of the battery cell and the insulation of the whole pack keep normal.

Devil Serial Test

The same battery undergoes 6 consecutive extreme conditions in series,

Soaking, burning, freezing, dragging, crushing, falling from a height.

After such a “Hell Journey”, the battery pack still did not catch fire or explode.

Safety is no small matter.

The VREMT 800V battery adopts a strategy of “internal and external prevention”,

Builds tangible and intangible “cages” to prevent thermal runaway in advance.

Based on user needs with safety as its top priority,

VREMT will continuously innovate, develop and apply the most advanced technology,

Empowering ultimate safety of the whole vehicle to put users’ worry about security of electric vehicles to an end.