V-Space is new column dedicated to explaining the technology of VREMT products and inspiring the future development of energy.

Leading the 800V ultra-fast charging era

Ultimate power efficiency, 800V power output

It has been 200 years since the birth of electric vehicles

Range and energy replenishment are still an obstacle

It’s also the biggest concern of new energy vehicle users

How to overcome it? High efficiency and low loss is the key

According to the formulas P=UI and Q=I²Rt

When the current is constant, the higher the voltage, the higher the power.

When the power is constant, the higher the voltage, the lower the current.

When the resistance is constant, the lower the current, the lower the loss.

Therefore, upgrading from the 400V platform to the 800V platform

Can save wiring harness and reduce internal resistance losses in the circuit

Achieving higher power density and energy efficiency

Which, in turn, improves the efficiency of the whole vehicle

1. The world's first mass-produced ultra-fast-charging lithium iron phosphate battery

VREMT 800V battery is the world's fastest mass-produced LFP battery

Maximum charge rate of 4.5C

15min of charging can extend the range by more than 500km

Even at -10℃

At least ¼ faster than similar products

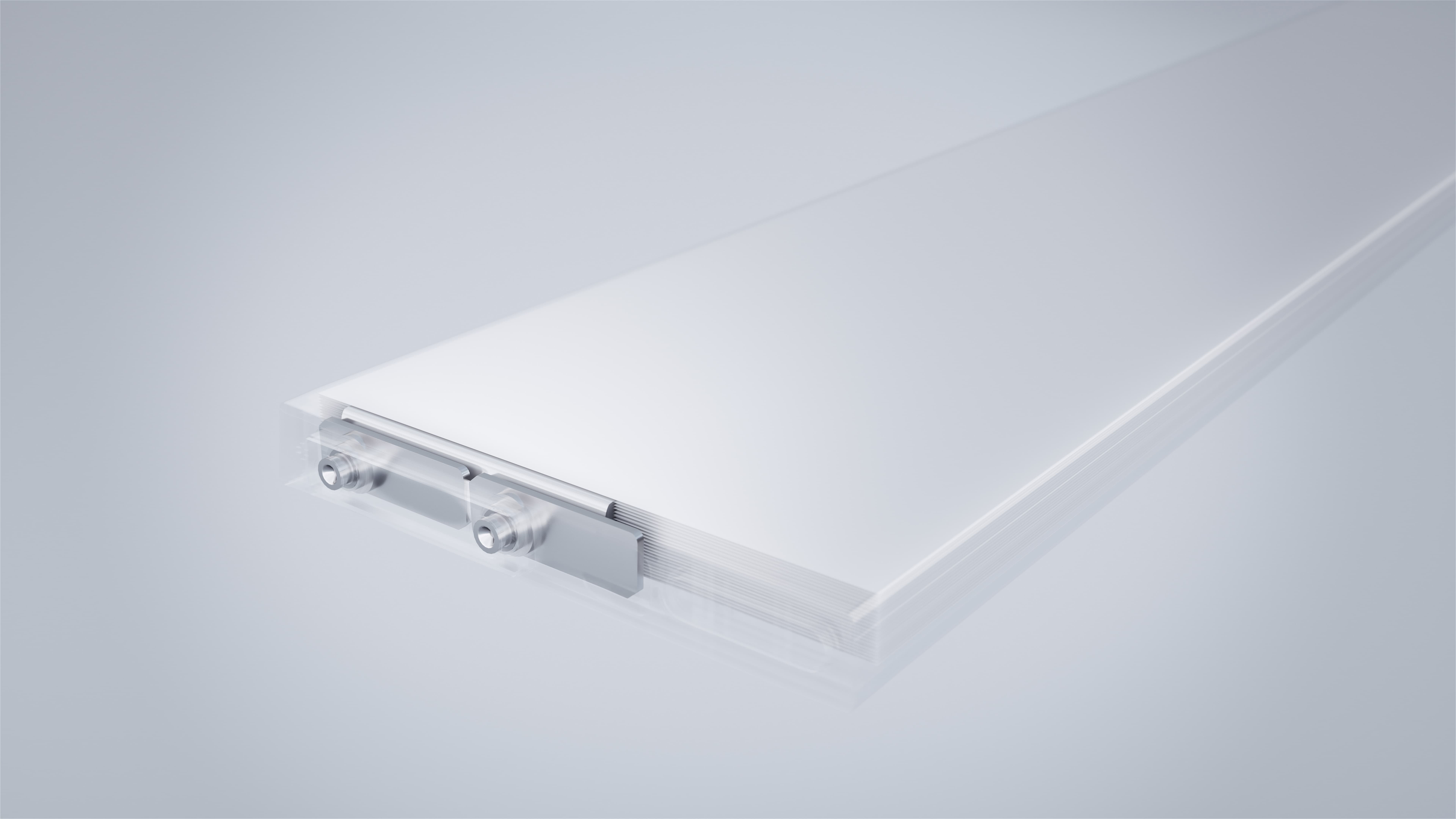

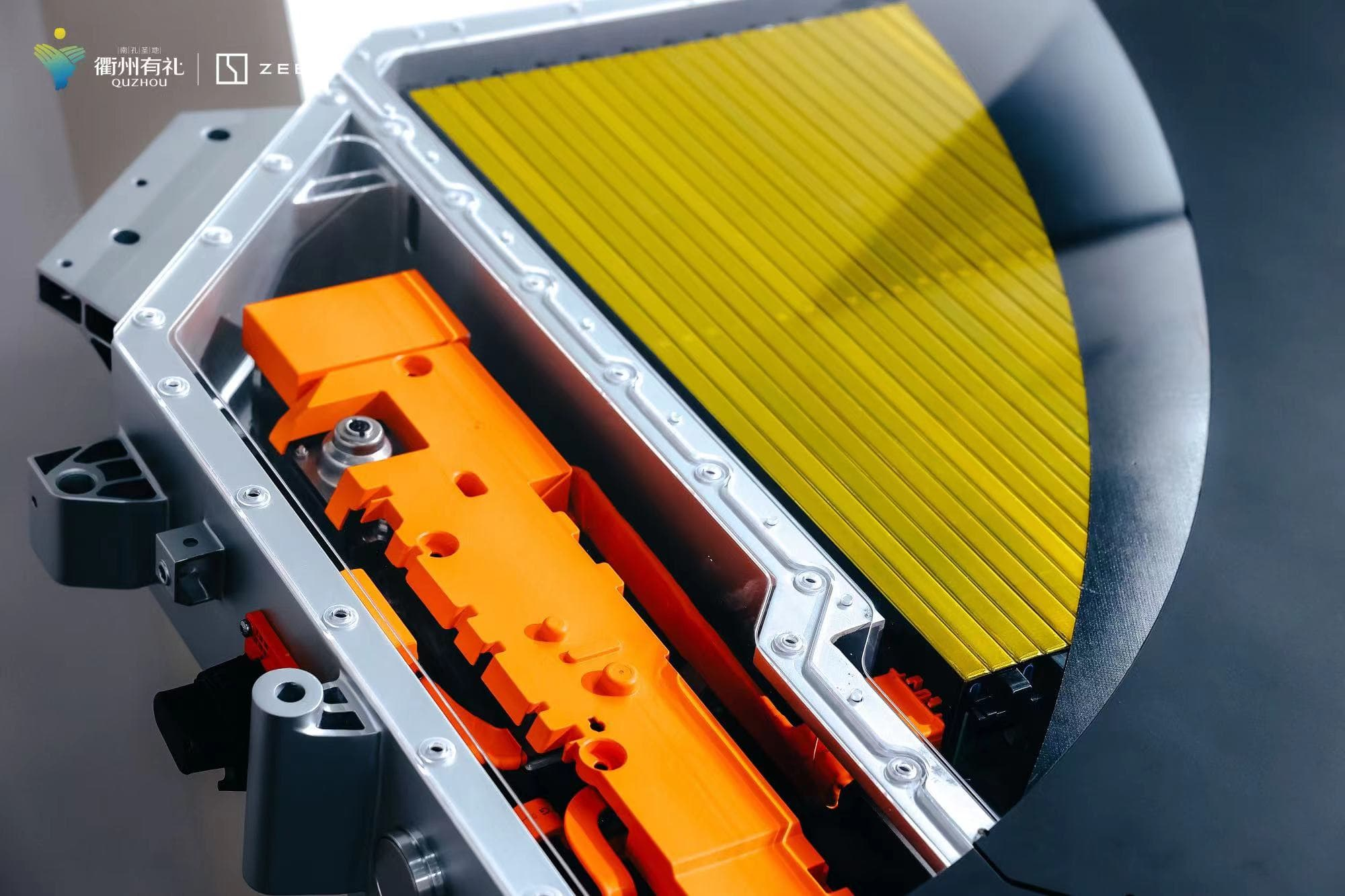

VREMT 800V battery pack adopts a number of innovative technologies

Dual-rivet post current guide design

The overcurrent capacity is 100% higher than that of single post solution

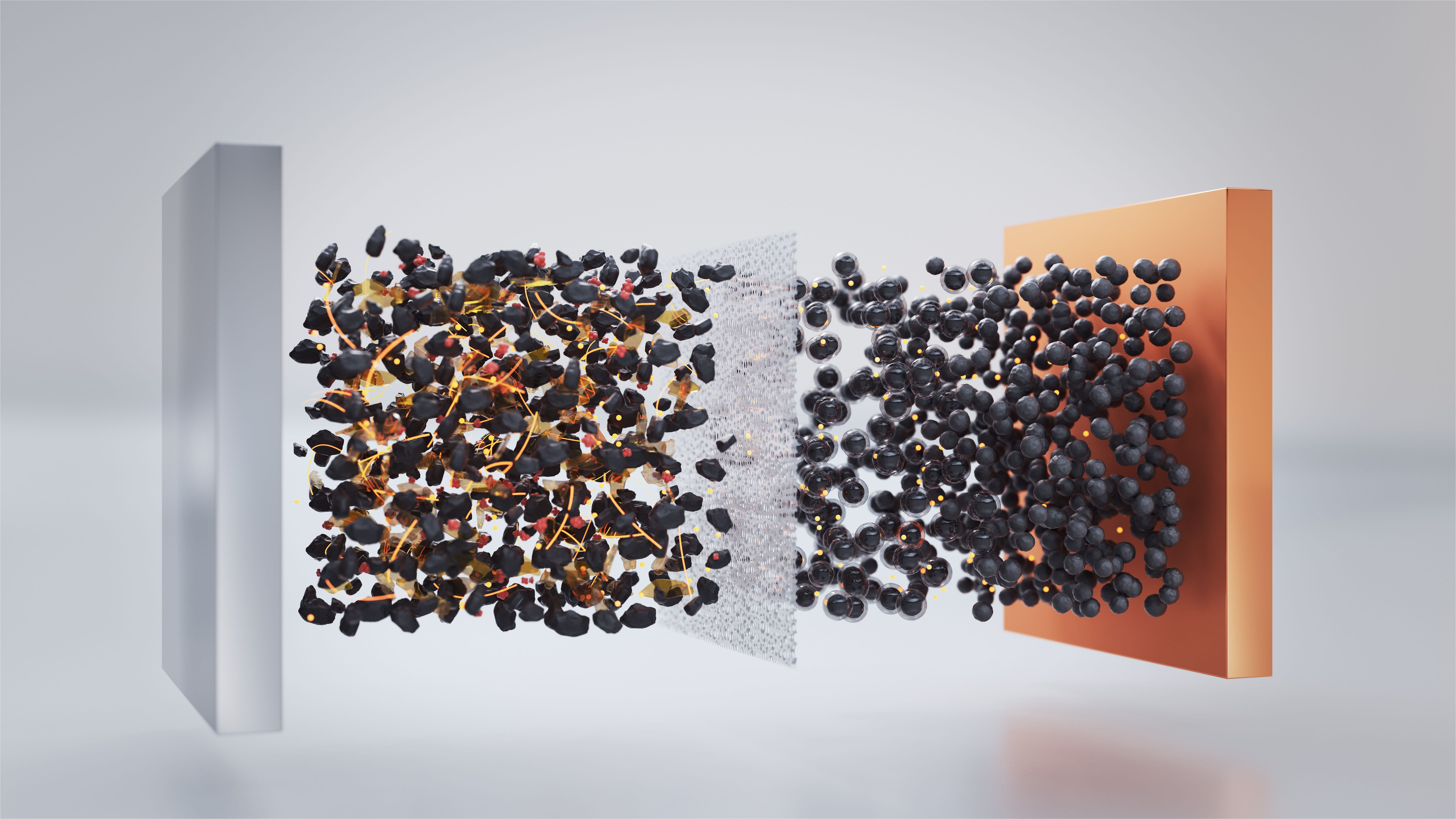

Stacked electrodes with multiple lugs

Uniform heat distribution and efficient temperature control in ultra-fast charging conditions

Lithium ion acceleration technology

Enhancing the efficiency of the whole process of lithium ion release, transmission and reception

More stable and efficient high-voltage high-current fast charging

3-second pulse discharge rate up to 16C

Allowing 3s 0-100 acceleration for high-performance pure electric models

Long-lasting acceleration and low power consumption in the mid-and rear-stages

2. The robust power battery that has passed the “Hell Journey" safety test

For 800V platforms, the voltage increase

Means higher requirements for battery pack insulation capability and voltage resistance level

VREMT 800V battery packs are designed with the world's most stringent safety standards

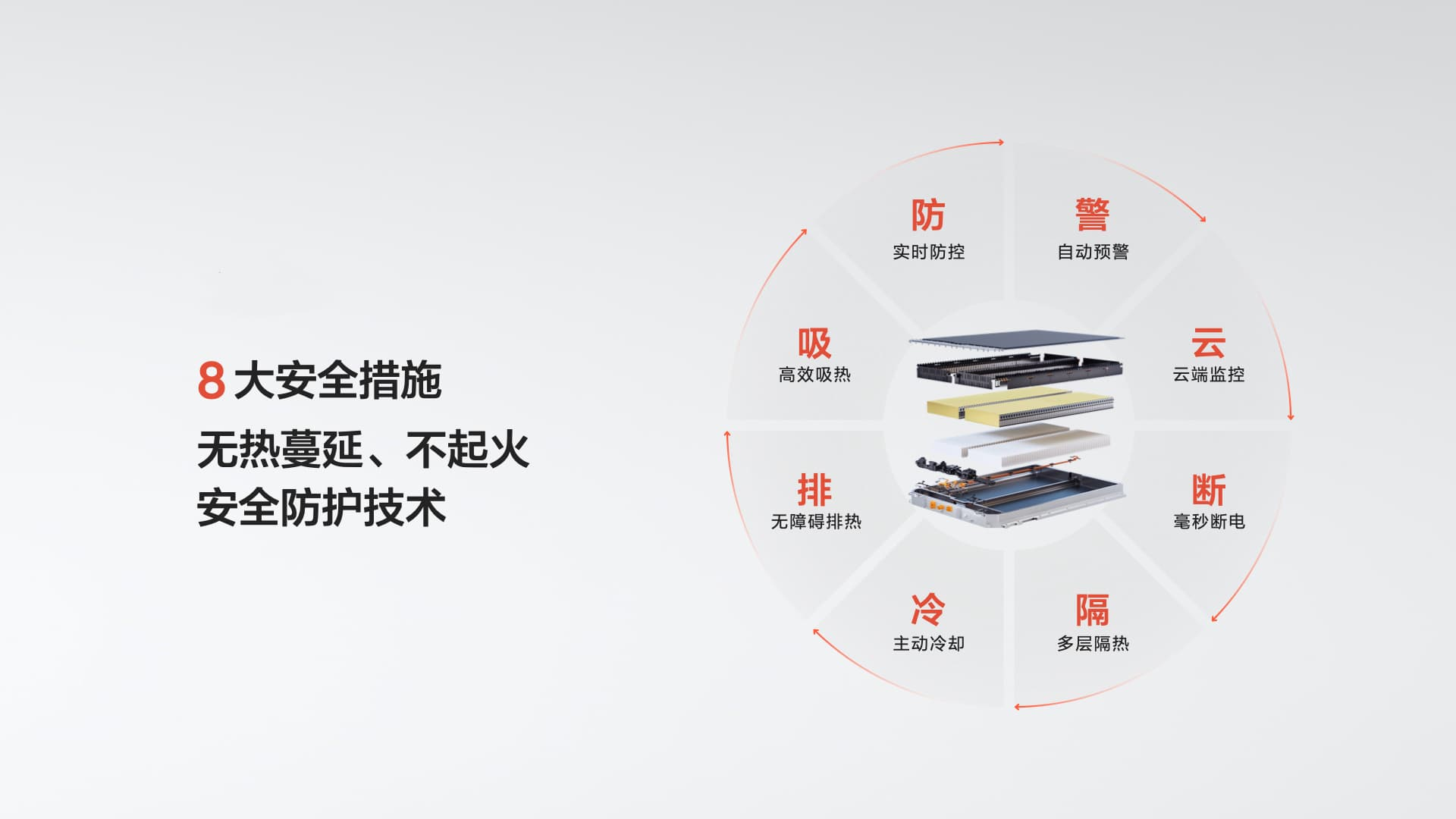

8 major thermo-safety protection technologies

Industry's first three extreme safety tests

Setting new safety standards for lithium iron phosphate batteries

Ultimate safety for new energy vehicles

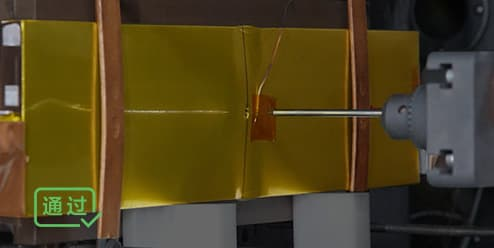

Overpressure needling

Squeezing the full-charged battery with 150kN force until the deformation reaches 30%+

No liquid leakage and no power loss after one hour of standing time

(The national standard is 100kN, and the deformation is more than 2 times of the national standard)

Then use 5mm steel needle to penetrate

No fire or explosion and the highest temperature of the surface is only 33.0℃

240S fire test

No fire or explosion, the voltage of the battery cell and the insulation of the whole pack is normal

(The national standard is 130s)

Devil serial test

Withstood 6 continuous extreme working conditions test, or the Devil serial test

Water, fire, freezing, dragging, crushing, falling

No fire or explosion

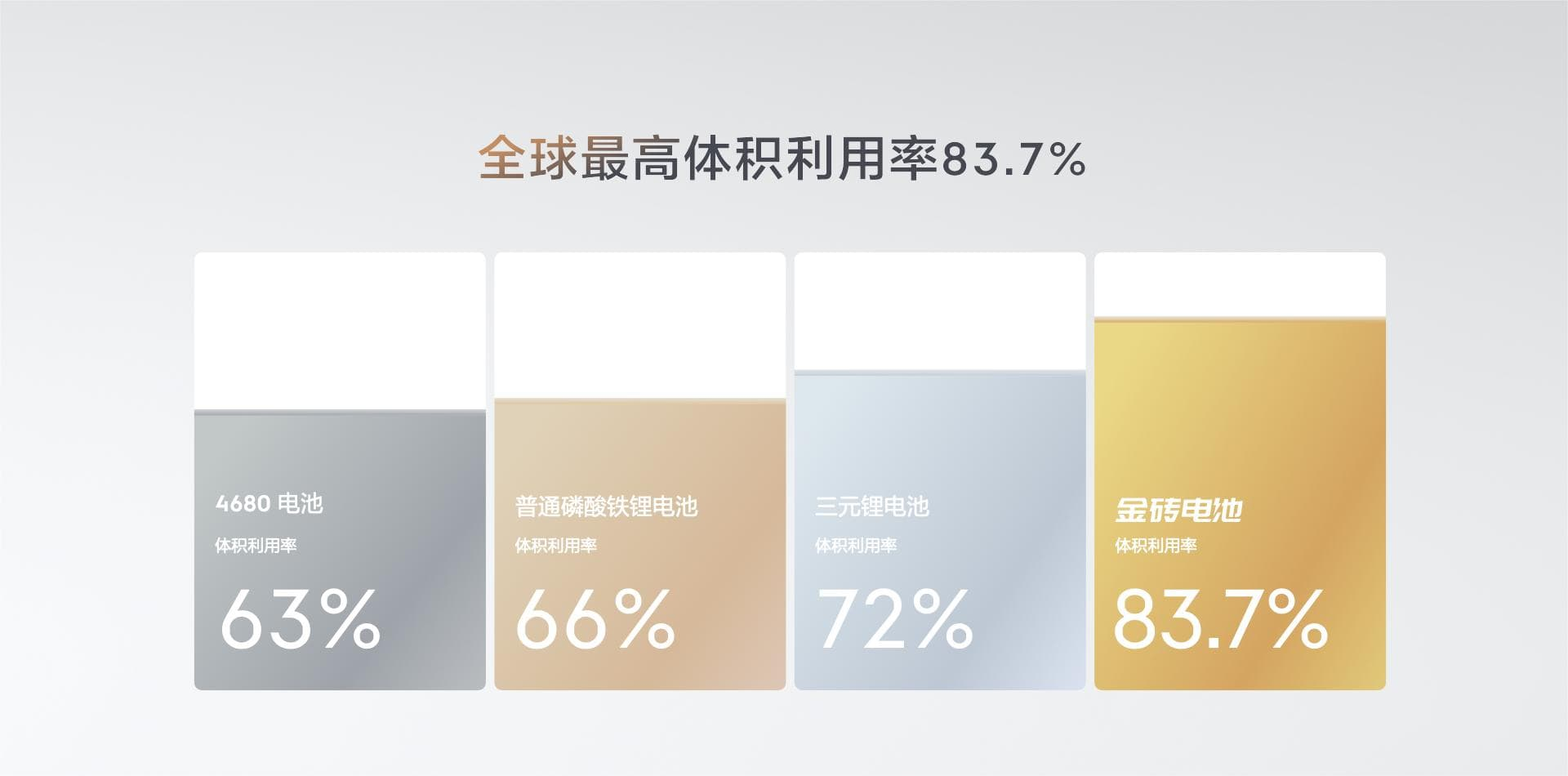

3.The range king with the highest volume utilization rate in the world

Integrated high-efficiency design greatly optimizes the internal structure of the battery

The volume utilization rate reaches 83.7%.

Compared with traditional NMC battery pack

Battery mass energy density increased by 10% +

Using lithium iron phosphate to achieve the range of NMC battery pack

The battery cell, the top cover and the soleplate for a “compact sandwich structure"

Freeing up longitudinal space in the cell compartment, 7.6% increase in volume utilization

Integrated liquid-cooled tray at the bottom of the battery

8.5% increase in volume utilization

Adopting aerospace grade ultra-thin thermal barrier material between battery cells

6% increase in volume utilization

Leading the industry with profound expertise

Stronger performance and strict production processes

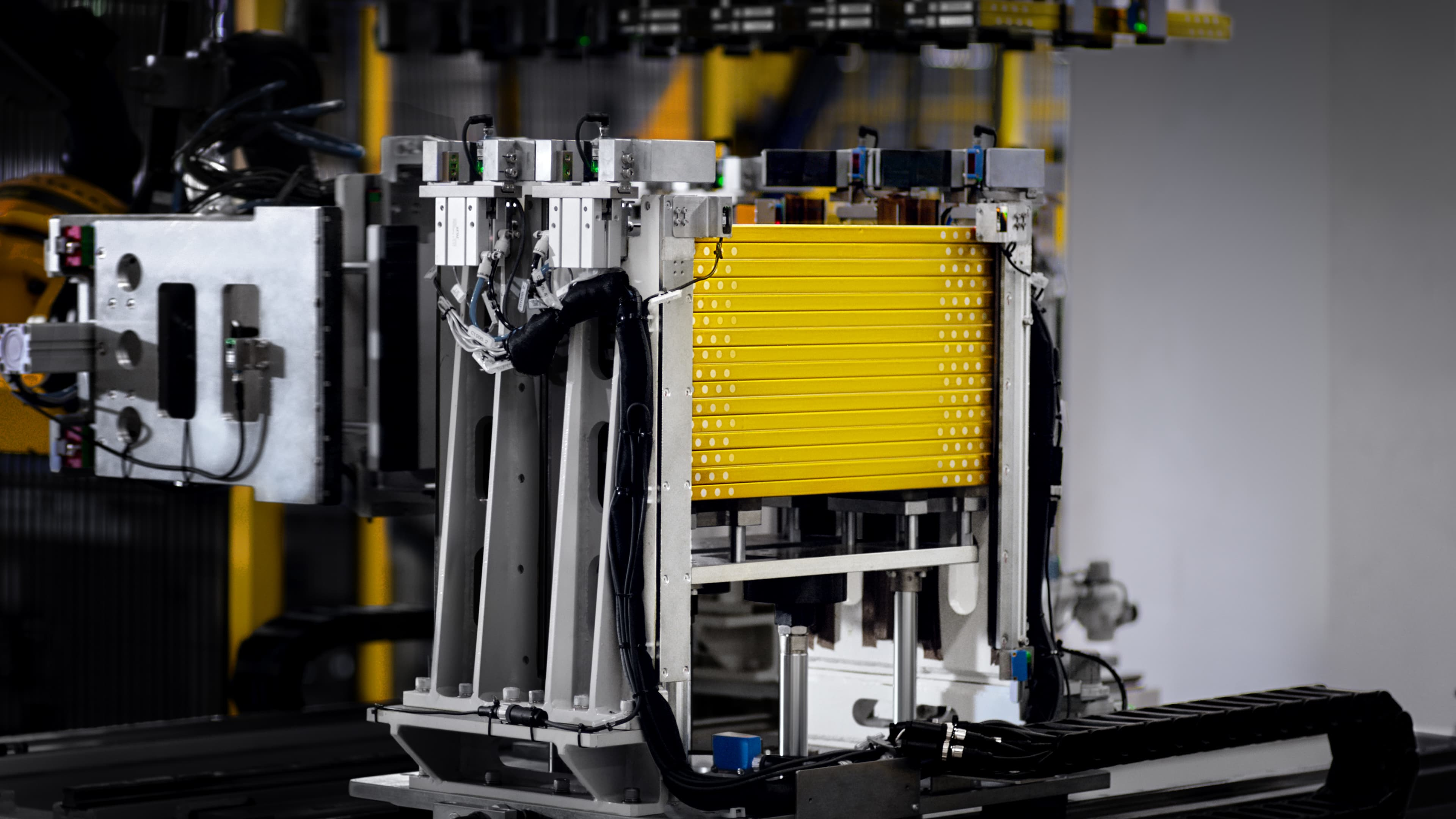

Took one and a half years, covering an area of 1,567 mu

The world's largest integrated base for intelligent manufacturing of EIC and energy storage systems

The 5G intelligent factory for EIC system - Quzhou Jidian Factory was officially completed

Dual pump coupling technology of pole piece, dual light control monitoring and feedback system

Realizing online real-time error correction and closed loop

Independently developed battery cell cluster stacking technology

Overcoming the industrial challenge of error accumulation in battery cell thickness

Ensuring the consistency of the expansion of battery cells, battery life increased by 10%

Full-process AI visual inspection system ensures highly consistent quality

(CCD full-size monitoring for five major processes, insulation pulse monitoring and 100% monitoring of product characteristics for three major processes)

From battery cell manufacturing to pack assembly

More than 200 tests far exceeding industry standards to ensure battery quality

VREMT always meets customer needs and promotes technological innovation

Fast-charging, safe and long-lasting 800V battery packs

For a convenient and 100% safe charging experience

Enhancing user experience and ushering in the high-power fast-charging era