VREMT Technical Strengths

Providing First-class Solutions with Pre-sighted Technology and System Advantages

Product R&D

Patent

Through the tireless efforts of over 3,000 R&D personnel, VREMT has applied for over 1,200 patents in R&D, application, manufacturing, and pilot production, including over 697 invention patents. These patents cover core technologies such as battery cells, modules, packs, BMS, motor control, and energy storage products, with phased international patent applications underway.

試験能力

威睿電動実験室の建築面積は37000平方メートルで、検査機器の投資額は約3億元で、現在検査及びサポートスタッフは合計162名で、うち、学士以上の人数が106名(占める割合は65%)、検査経験が5年以上の者が130名(占める割合は80%)です。電池領域の試験専門家1名。試験領域は、材料及び電気化学、駆動用バッテリー、モーター電気制御、充電システム、エネルギー貯蔵システム、電磁両立性EMC、環境信頼性試験等をカバーしており、材料レベルから部品レベル、さらにはシステム共同デバッグレベルまでの試験能力を備えており、GB、ISO、UN、UL、ECE等の国内外の試験基準、及び吉利(Geely)、VOLVO、領克(Lynk&Co)等の企業の基準を満たしています。実験室はISO/IEC 17025規格の要件に厳密に従って設立及び運営されており、中国合格評定国家認可委員会CNAS及び吉利グループSQEの認定を取得しています。同時に、実験室はTÙV UNregulation No.100によって認定されたWTDP (ウイットネス・テストデータ・プログラム) 実験室です。2021年に国家電網供電公司杭湾供電分公司と「寧波前湾新型電力システム(エネルギー貯蔵)共同実験室」を共同で設立しました。

駆動用バッテリーの試験

環境信頼性試験

モーター電気制御試験

充電システムの試験

Quality Assurance Capability

Comprehensive and Reliable Full-process Quality Management

The company implements a full-process quality management system encompassing R&D, manufacturing, continuous improvement, and supplier management. This commitment to quality has earned the trust of customers including Zeekr, Geely, Geely Galaxy, Lynk & Co, Geometry, Volvo, Polestar, and smart.

Robust Hardware and Software Quality Assurance

The company obtains IATF 16949 quality management system certification, ISO/IEC 17025 CANS laboratory certification, ASPICE Level -2 process certification, ISO 26262 functional safety product certification, and A-level evaluation of Geely's full-process competitiveness quality system.

Advanced and Scientific Testing and Analysis Capabilities

The company possesses components and assemblies ranging from automotive-grade to industrial-grade. Key assets include a power battery EOL (End-of-Life) testing system, an electric drive NVH Discom test bench, a 100% burn-in testing system for electronic controls, a three-coordinate precision measurement laboratory, a standardized metallographic laboratory, a cleanliness analysis laboratory, and a gear measurement center.

生産製造

Battery Production Line

5 automatic production lines, 7 flexible production lines, compatible with 0.38~102kWh power-range product sequence, the annual production capability of 960,000 sets of battery systems; first-class equipment brands for testing, laser welding, screw locking, six-axis robot module assembly, AGV online and offline logistics turnover and other processes

Develop and verify first-class module and PACK process technology with continuous and stable mass production

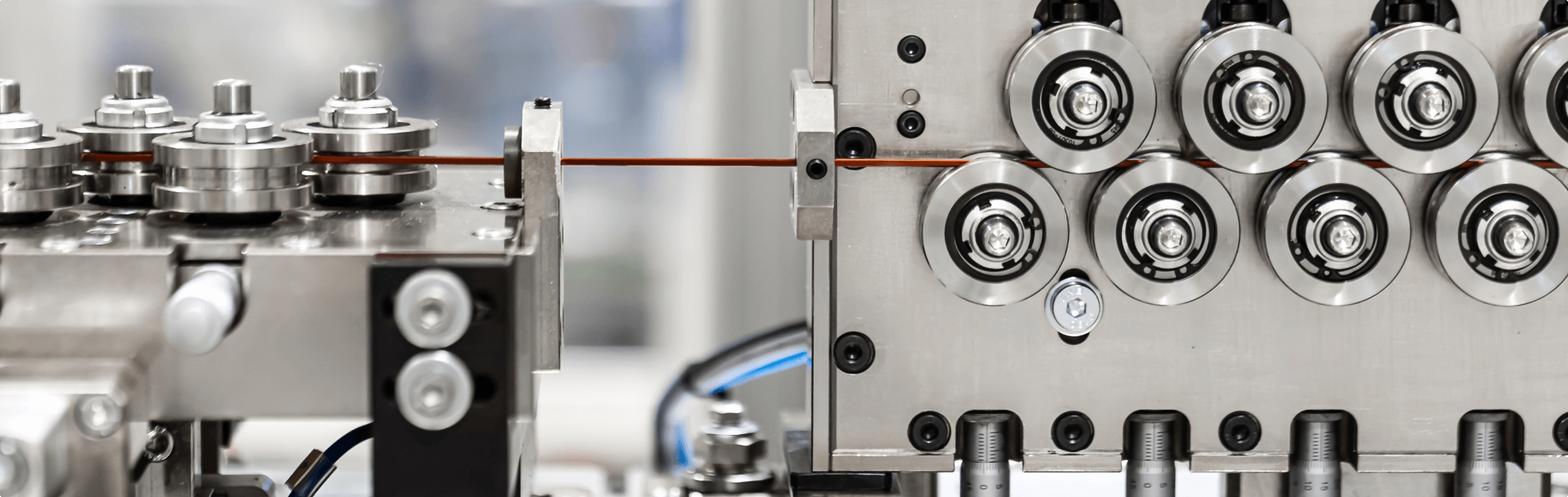

EDS Line

Seven production lines are for EDS1, EDS2 three-in-one assembly, and ICS charging product service. The EDS1 production line is composed of a stator line, an electric control line, a general assembly line and a test line, with an annual output of 150,000 sets; The annual output of EDS2 production line is 80,000 sets and that of ICS production line is 53,000 sets; Among them, the EDS1 stator line adopts the manufacturing process of 8-layer hairpin flat wire, and the whole line is introduced by Italian ATOP company

Advanced technology and first-class manufacturing and testing equipment ensure the high-quality products

E&E Production Line

There are CSC automatic production line and BMU/CVS automatic production line, of which CSC is the fastest fully automatic production line in the domestic BMS industry at present. It has modular design, high flexibility and compatibility, and can realize the exchange of single work stations, manual and automatic integration, free combination, and real-time monitoring by mobile terminals

Four advantages: team experience analysis, standard library, CBA software analysis ability DFX, and new process R&D, to achieve the seamless connection between product R&D and product industrialization

Supercharger Production Line

The supercharging product line is compatible with a wide range of commercial liquid-cooling and conventional charging cabinets and piles, including V1, V2, V2.1, and V3. The assembly process employs RGV for high-precision positioning, stability, and efficient transportation. UV printing and laser printing technologies enable personalized product customization

Critical process steps are initiated through MES, executed on the production line, and then confirmed by equipment feedback, ensuring consistent product quality

Energy Storage Production Line

Ring facula with two independently controllable optical paths allows individual setting of the waveform and power of both the inner and outer rings. This design excels in spatter suppression and typically employs the inner ring for deep penetration welding and the outer ring for aesthetic finishing. Comprehensive testing capabilities, including on-off testing, insulation resistance testing, and capacity verification to ensure the performance and quality of both PACK-level and cluster-level products. The integration of heavy-duty AGVs, a range of testing functions, cross-transport vehicles, and intelligent tool carriers enables real-time monitoring and intelligent scheduling for optimized production

This production line boasts a high level of automation and scalability, making it compatible with the manufacturing of various product models. Its straight-through layout ensures efficient and streamlined material handling, eliminating unnecessary backtracking. Comprehensive MES (Manufacturing Execution System) control allows full traceability of process data, guaranteeing the output of high-quality products. The modular design of the production line enhances flexibility, enabling it to cater to the manufacturing of diverse energy storage system products